13

oPeraTinG insTruCTions

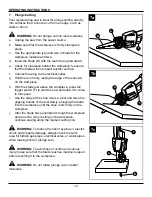

8. Metal Cutting

The saw can be used to cut metals, such as sheet steel, pipe, steel rods, aluminum, brass, and

copper. Be careful not to twist or bend the saw blade. Do not force the tool.

The use of cutting oil is recommended when cutting soft metals and steel. Cutting oil will keep the

blade cool, increase cutting action, and prolong blade life.

WarninG:

Never use gasoline as cutting oil; normal sparking could ignite the fumes.

a. Securely clamp the workpiece in position, and make the cut close to the clamping point to

minimize vibration.

b . When cutting conduit pipe or angle iron, clamp the workpiece in a vise. If possible, cut close to

the vise to prevent the workpiece from shaking and to prevent kickback.

c . To cut thin sheet material, sandwich the material between pieces of hardboard or plywood and

clamp the layers together to reduce vibration and tearing of the material.

Care and mainTenanCe

WarninG:

All maintenance should only be carried out by a qualified repair person.

Cleaning

Before cleaning or performing any maintenance, disconnect the tool from the power source. For safe

and proper operation, always keep the tool and its ventilation slots clean. Only use a soft, dry cloth to

clean your saw. Never use any detergent or alcohol.

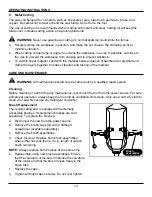

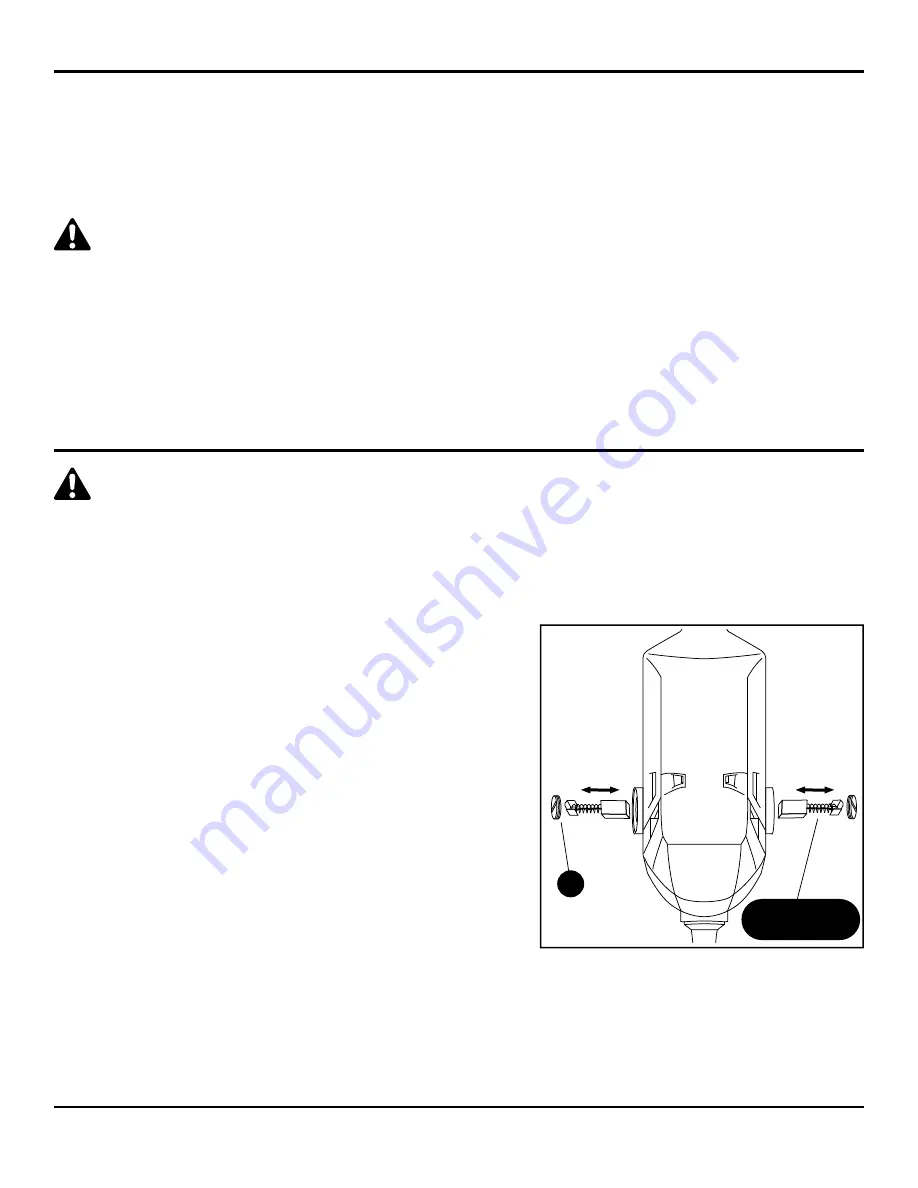

Brush Replacement

The reciprocating saw is equipped with externally

accessible brushes. Replacement brushes are sold

separately. To replace the brushes:

a. Disconnect the saw from the power source.

b . Remove the brush caps (G) with a flathead

screwdriver (available separately).

c . Remove the brush assemblies.

d . Check for wear. Replace both brush assemblies

when either has less than a 1/4 in. length of carbon

brush remaining.

noTe:

Always replace both brushes at the same time.

e . Reassemble using new brush assemblies. Ensure

that the curvature of the brush matches the curvature

of the motor and that the brush moves freely in the

brush tube.

f. Replace the caps.

g. Tighten all brush caps securely. Do not over tighten.

Brush

assemblies

G