18

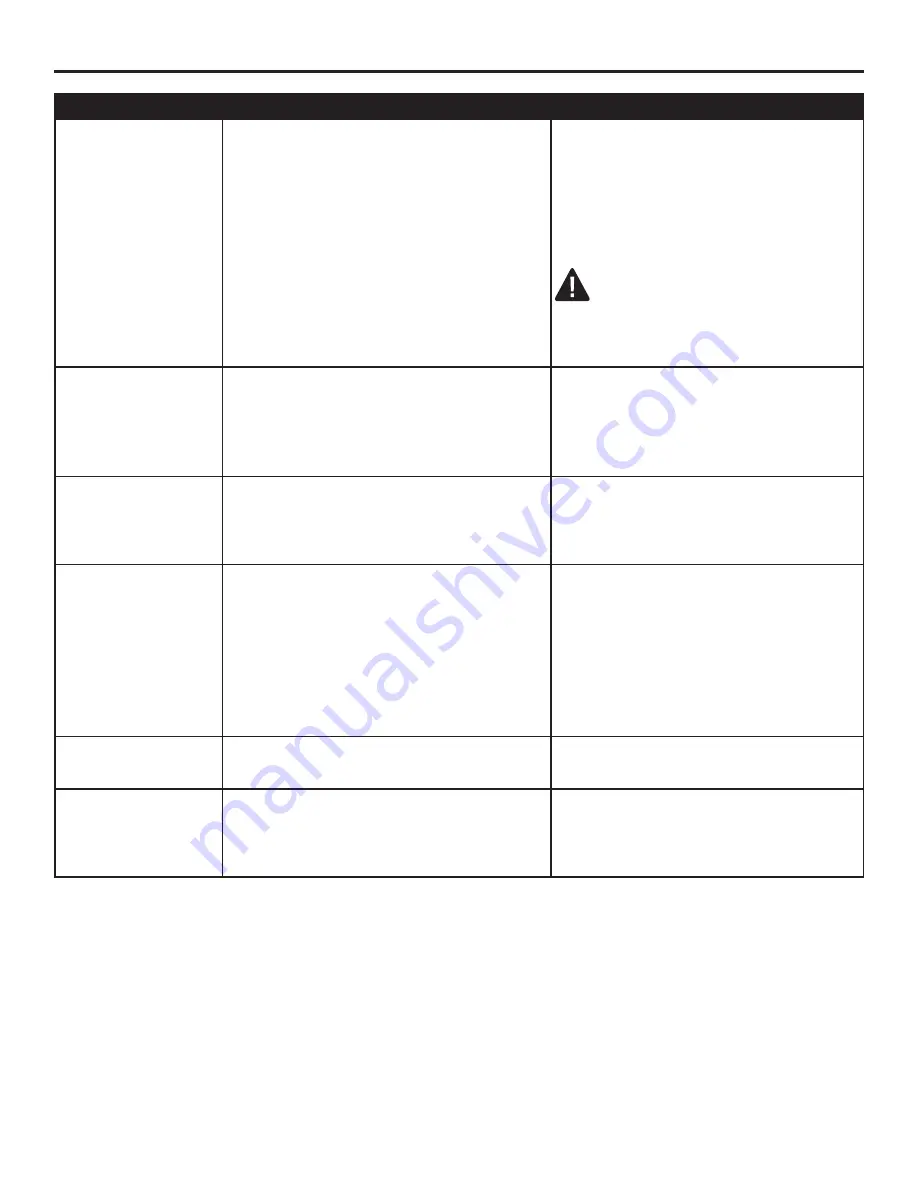

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

The air receiver

pressure drops

when the

compressor shuts

off.

1. The connections are loose or leaking

(fittings, tubing, etc.).

2. The drain valve is loose.

3. The check valve is leaking.

1. Check all the connections with

soapy water and look for bubbles.

Tighten any loose conections until

the leak stops.

2. Tighten the drain valve.

3. Take the compressor to a service

center.

WARNING:

Do not disassemble

check valve while air is in tank.

Empty the all the air out of the tank

before dissasembly.

There is excessive

moisture in the air

discharge.

1. There is excessive water in the air

tank.

2. The humidity is high.

1. Drain the tank to remove water.

2. Move the compressor to an area of

less humidity or use an air line filter

to reduce moisture discharge in the

tank.

Air is leaking from

the compressor.

1. The hose connection is loose or

improperly sealed.

2. The air hose is broken or damaged.

1. Ensure connections are sealed

with thread sealing tape and

tightened.

2. Replace the air hose.

The compressor

runs continuously.

1. The tank drain valve is open.

2. The pressure switch is defective.

3. The usage is excessive.

1. Ensure the tank drain valve is

closed.

2. Take the compressor to a service

center.

3. Decrease the amount of tool

run-time; the compressor is not

large enough to supply the air

requirement of the tool.

The compressor

vibrates.

1. The compressor mounting bolts are

loose.

1. Tighten mounting bolts.

The air output is

lower than normal.

1. The inlet valves are broken.

2. The connections are leaking.

1. Take the compressor to a service

center.

2. Apply thread sealing tape to fitting

and tighten.

TROUBLESHOOTING