4

PARTS DESCRIPTION

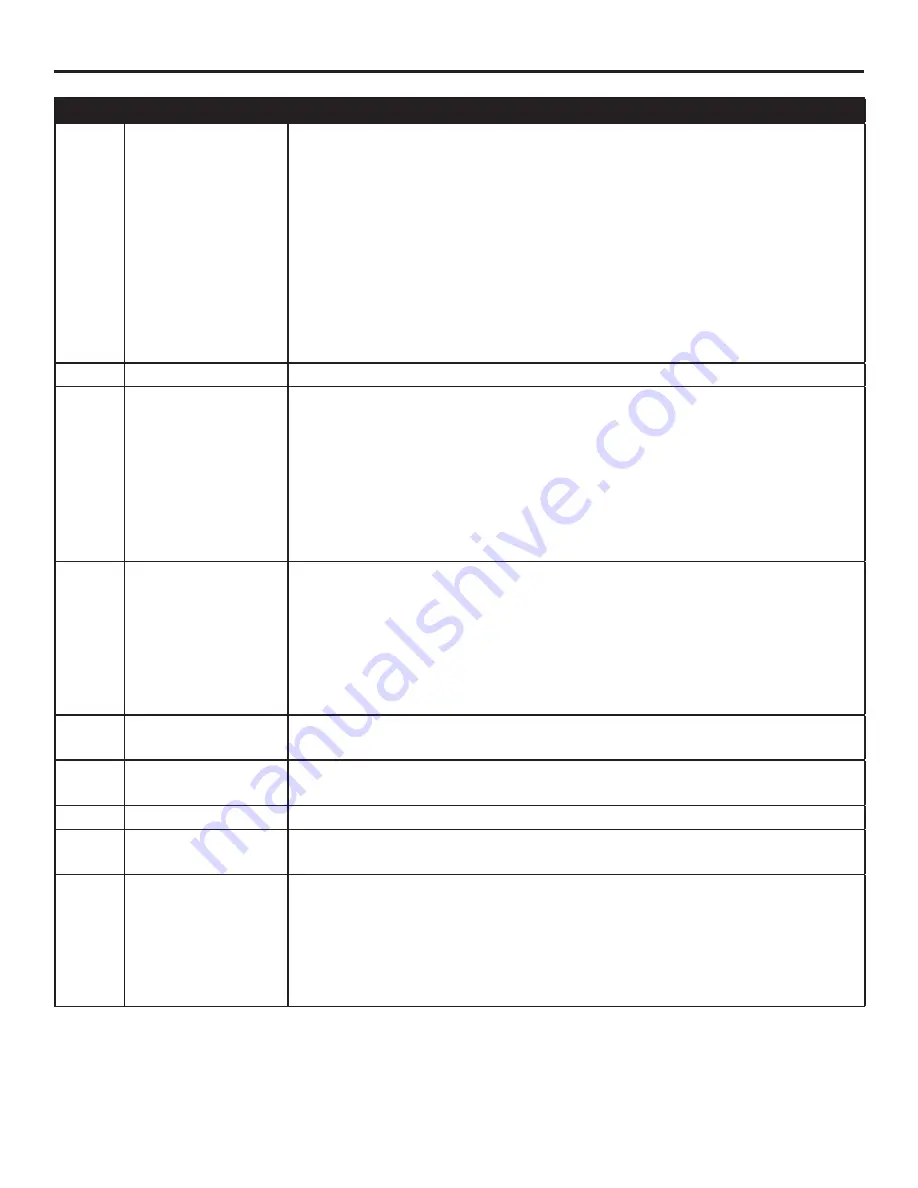

PART

NAME

DESCRIPTION

A

Electric motor &

air compressor

pump

The motor is used to power the pump. The electric motor has a

thermal overload protector. If the motor overheats for any reason,

the thermal overload will cut off power, thus preventing the motor

from being damaged. Wait until the motor is cool. Motor resets

automatically.

Air compressor pump: to compress air, the piston moves up and down

in the cylinder. On the down stroke, air is drawn in through the air

intake valve while the exhaust valve remains closed. On the upstroke,

air is compressed, the intake valve closes and compressed air is

forced out through the exhaust valve, into the discharge line, through

the check valve and into the air tank.

B

Air tank

The tank is used to store the compressed air.

C

Manual ON/OFF

switch

This switch is used to start or stop the air compressor. Moving the

switch to the (ON) position will provide automatic power to the

pressure switch which will allow the motor to start when the air tank

pressure is below the factory set cut-in pressure. When in the (ON)

position, the pressure switch stops the motor when the air tank

pressure reaches the factory set cut-out pressure. Moving the switch

to the (OFF) position will remove power from the motor and stop the

air compressor.

D

Pressure regulator

knob

Use the pressure regulator knob to adjust the amount of air being

delivered through the hose.

The air pressure coming from the air tank is controlled by the regulator

knob. Turn the pressure regulator knob clockwise to increase

discharge pressure and counterclockwise to decrease discharge

pressure. Follow tool operating instructions for recommended pressure

range.

E

Tank pressure

gauge

The tank pressure gauge indicates the pressure of the air in the tank.

F

Regulator

pressure gauge

The current line pressure is displayed on the regulator pressure gauge.

This pressure can be adjusted by rotating the pressure regulator knob.

G

Quick coupler

The outlet is used to connect the 1/4 in. NPT air hose.

H

Drain valve

The drain valve is used to remove moisture from the air tank after the

air compressor is shut off.

I

Safety valve

This valve is designed to prevent system failures by relieving pressure

from the system when the compressed air reaches a predetermined

level. The valve is preset by the manufacturer and must not be

modified in any way. To verify the valve is working properly, pull on

the ring. Air pressure should escape. When the ring is released, it will

reset.