22

CARE AND MAINTENANCE

Chain maintenance

For smooth and fast cutting, the chain needs to be maintained properly. The following conditions

indicate that the chain requires sharpening:

• Wood chips are small and powdery.

• Chain must be forced through the wood during cutting.

• Chain cuts to one side.

During maintenance of the chain, consider the following:

•

Improper filing angle of the side plate can increase the

risk of severe kickback.

• Depth gauge (or raker clearance) setting determines

the height the cutter enters the wood and the size of

the wood chip that is removed. Too much clearance

increases the potential for kickback. Too little clearance

decreases the size of the wood chip thus decreasing the

chain’s cutting ability.

• If cutter teeth have hit hard objects such as nails or

stones, or have been abraded by mud or sand on the

wood, have service dealer sharpen chain.

How to sharpen the cutters

Be careful to file all cutters to the specified angles and to

the same length, as fast cutting can be obtained only when

all cutters are uniform.

• Tighten the chain tension enough that the chain does

not wobble. Do all of your filing at the midpoint of the bar.

Wear gloves for protection.

•

Use a round file and holder.

•

Keep the file level with the top plate of the tooth. Do not

let the file dip or rock.

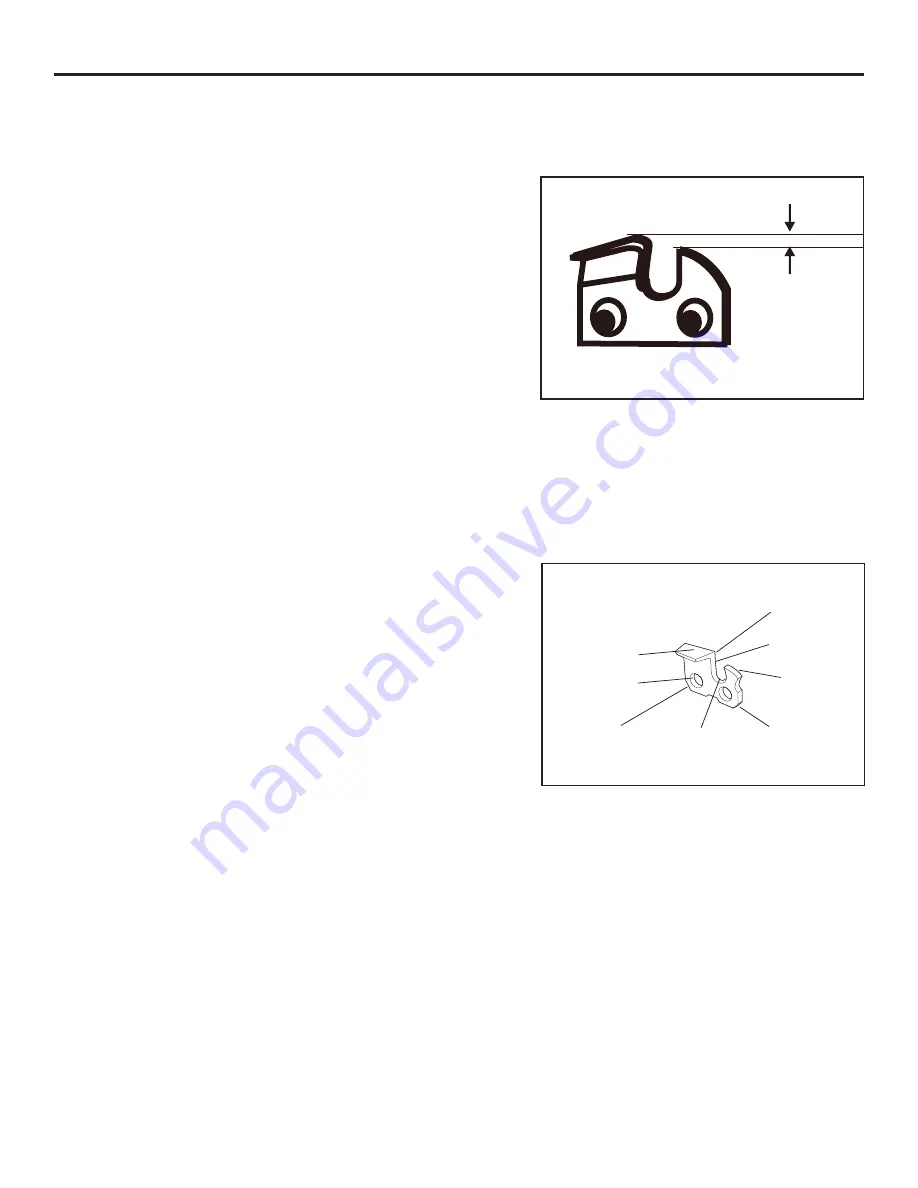

Raker (Depth Gauge) Clearance

1/32” (0.79mm)

PARTS OF A CUTTER

Cutting Corner

Side

Plate

Depth

Gauge

Toe

Gullet

Heel

Rivet Hole

Top Plate