OPERATING INSTRUCTIONS

CARE AND MAINTENANCE

An in-line oiler is not provided however recommended to be installed to the air supply

line to increases tool life and keeps the tool in sustained operation. The in-line oiler

should be regularly checked and filled with air-tool oil. Proper adjustment of the

in-line oiler is performed by placing a sheet of paper next to the tool’s exhaust ports

and holding the throttle open approximately 30 seconds. The in-line oiler is properly

set when a light stain of oil collects on the paper. Excessive amounts of oil should be

avoided.

In the event that it becomes necessary to store the tool for an extended period of

time, it should receive a generous amount of lubrication before storing the item. The

tool should be run for approximately 30 seconds to ensure oil has been evenly

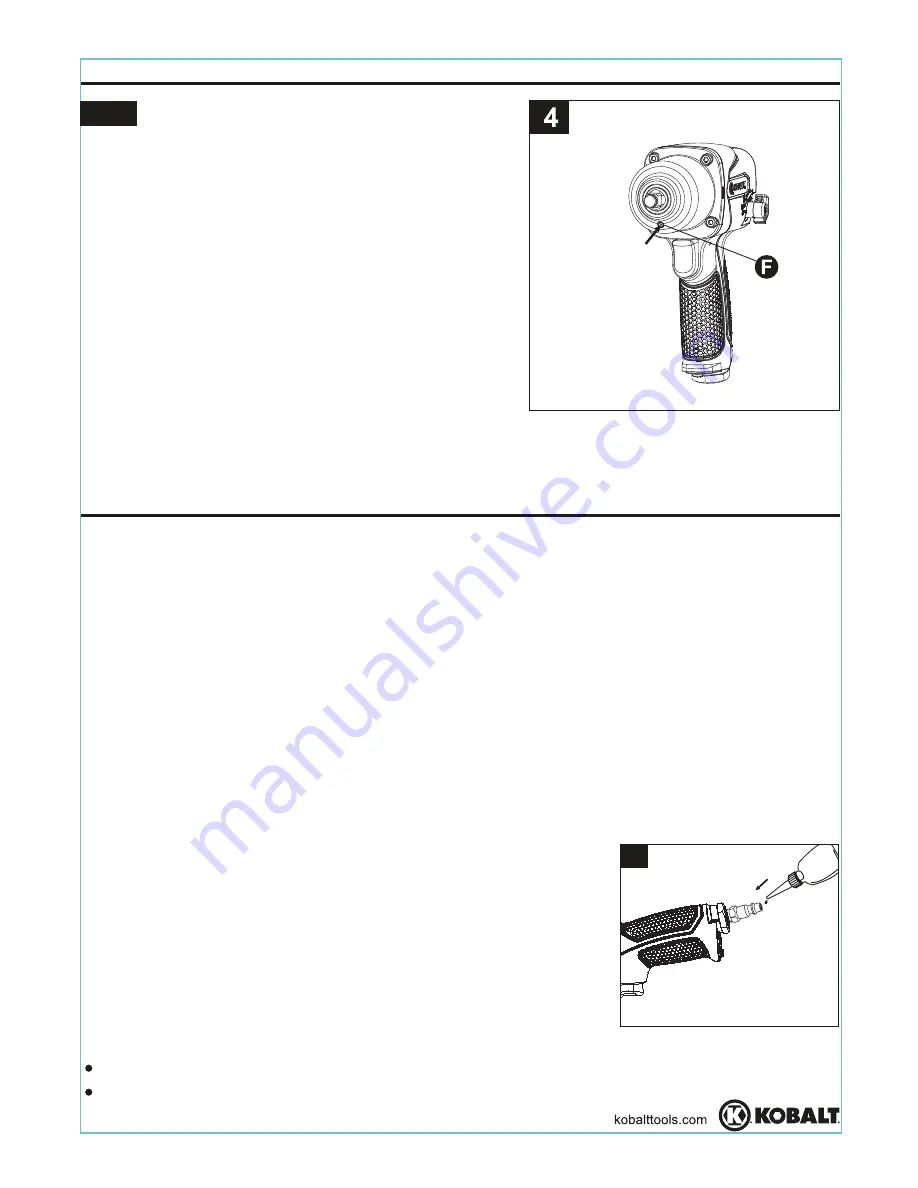

Recommended lubricants: For proper care and

maintenance use 3 drops of air tool oil, or any other

Clean the tool all over with a cotton rag after each use.

high-grade turbine oil containing moisture absorbent,

rust inhibitors, metal wetting agents and an EP (extreme

pressure) additive (not included). (See Figure 1)

distributed throughout the tool. The tool should be stored in a clean and dry

environment.

12

1

Storing

Impact Wrench must be well cleaned and lightly lubricated

Store Impact Wrench in a dry and safe place out of reach of children

NOTE

This tool features a weep hole (part F) on

the front protective cover. The weep hole (part F)

allows excess air to be released from the impact

wrench automatically while still lubricating the

tool when the proper lubrication instructions are

followed. (See figure 4)