12

ASSEMBLY INSTRUCTIONS

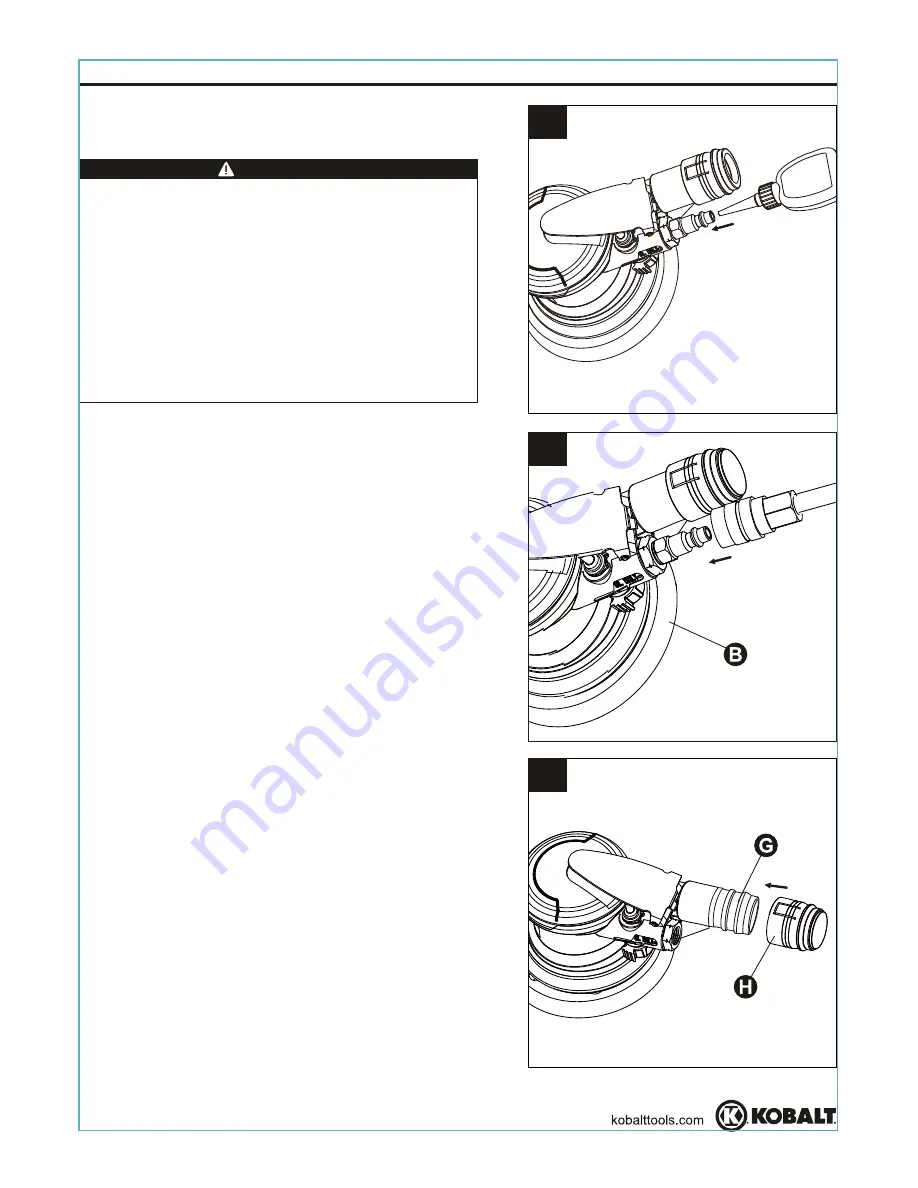

5

4. Mount sandpaper (not provided) onto the

sanding pad following the appropriate instructions.

5. Place 2 – 3 drops of air tool oil (not included)

into the male air plug before each use, as shown

in Fig. 4.

WARNING

Use only sandpaper with an RPM rating

equal to or greater than the tool itself.

Always make sure all attachments are

properly mounted and secure before using

the tool. Loose attachments can break or fly

off, causing serious injury to the operator or

bystanders in the work area. Always follow

all manufacturers’ specifications for proper

attachment and use.

t

NOTE:

Proper lubrication is EXTREMELY

important to assure proper tool performance

and avoid tool damage. ALWAYS lubricate the

ool before each use if not using an in-line oiler.

7. Connect the air supply hose to the male plug as

shown in Fig. 5, making sure it is completely seated

and secure. Set the working pressure at 90 PSI for

best tool performance.

NOTE:

To operate correctly, this tool requires

airflow of at least 6.4 cubic feet per minute (CFM)

at 90 pounds per square inch (PSI) at the tool.

8. This tool features a vacuum adapter (G) with

revolving tube attachment (H) to prevent tangling

when used with a dust-collecting vacuum system

as shown in Fig. 6. To connect it, remove the plastic

protective cap (I)

from the revolving attachment;

be

sure to save the cap.

If NOT using a dust-collection system, make sure the plastic protective cap is securely

in place on the revolving attachment to prevent blowing dust.

6. Make sure compressor air supply hose has

correct fittings installed at each end: male coupler

goes to compressor, 1/4 in. female coupler matches

up to 1/4 in. male plug installed on the tool.

4

6