26

kobalttools.com

Water-Based Paint:

. For long-

suited for your sprayer.

Oil-Based Paint:

Follow cleaning stages exactly. When cleaning after using oil-based paint or stains, using mineral

spirits or a cleaning mixture is recommended. Consult your local retailer for additional information on

the cleaning solvent materials best suited for proper cleaning. Consult your local retailer for additional

.

CARE AND MAINTENANCE

STAGE 1: Clearing Excess Paint

Flush any remaining paint or stain from the sprayer into waste pails to clear excess paint from the

system.

Note:

If outdoor garden hose connection with water supply is available, unscrew inlet screen (I)

turning clockwise at the end of the suction tube (B). Connect the suction tube to garden hose end (not

included) and tighten turning counterclockwise. Connect the other end of garden hose (not included)

to water spigot and tighten by turning counterclockwise. If no garden hose connection is available,

use water in a 5 gallon bucket.

NEVER

let the clean water bucket run out of clean water.

7. Turn power switch on and allow excess paint to flow out of prime tube (C) into waste pail.

8.

the system.

9.

sure both tubes are in the clean water bucket.

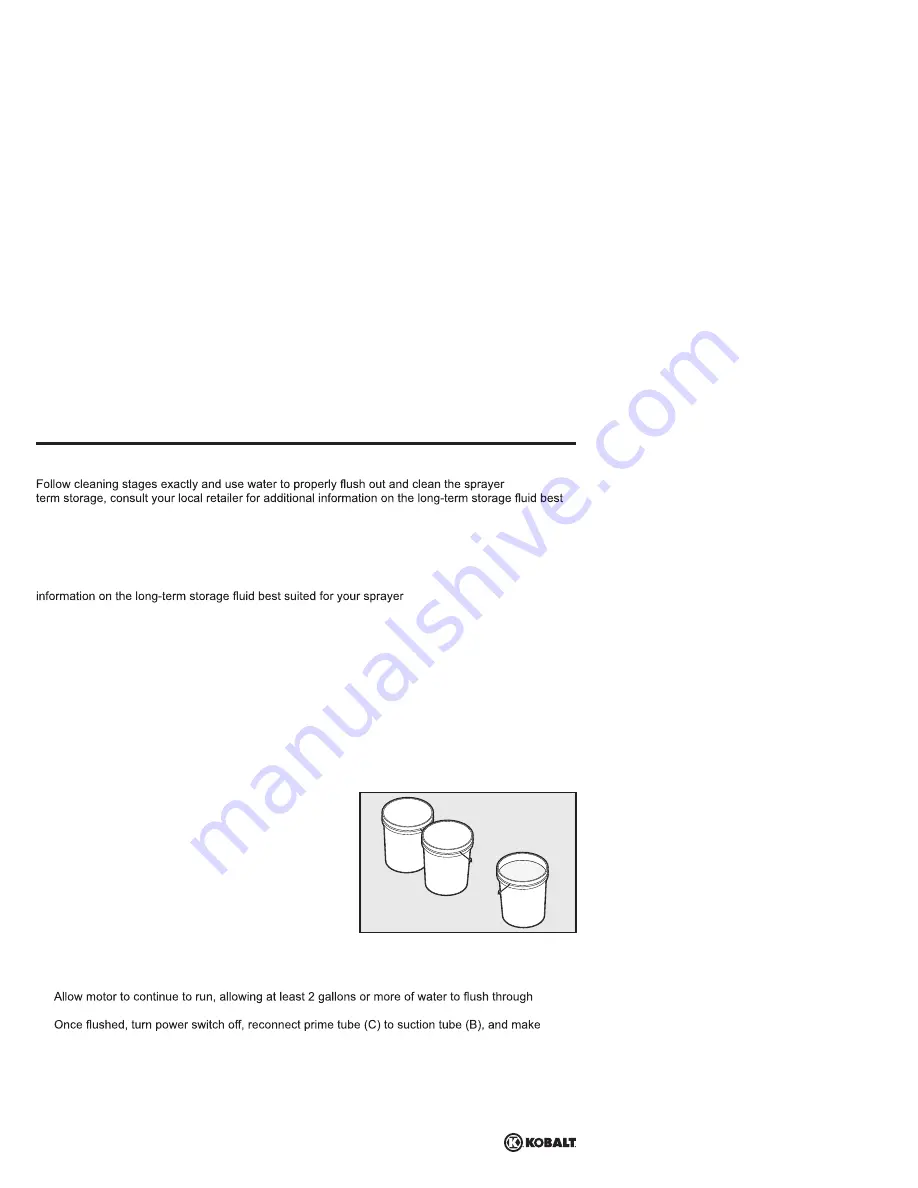

Waste Pails

Clean Water

Removing Excess Paint from Prime Tube

1. Relieve the pressure by turning prime spray valve

switch (H) to prime position.

2. Turn power switch off. Set safety lock to locked position.

3. Turn pressure control knob (F) clockwise to prime/

clean position.

4. Fill one 5 gallon bucket with clean water. Place suction

tube (B) in clean water bucket.

5.

n

Set two empty buckets, side by side, next to the clea

water bucket. These two buckets are the waste pails.

6. Place prime tube (C) in waste pail.

If mineral spirits or thinner is

used, brush components clean and thoroughly rinse with clean water to prevent seals from drying out.