Page 3-41

Dynamic Acera 03/05 Rev. 05

MACHINE FAMILIARIZATION

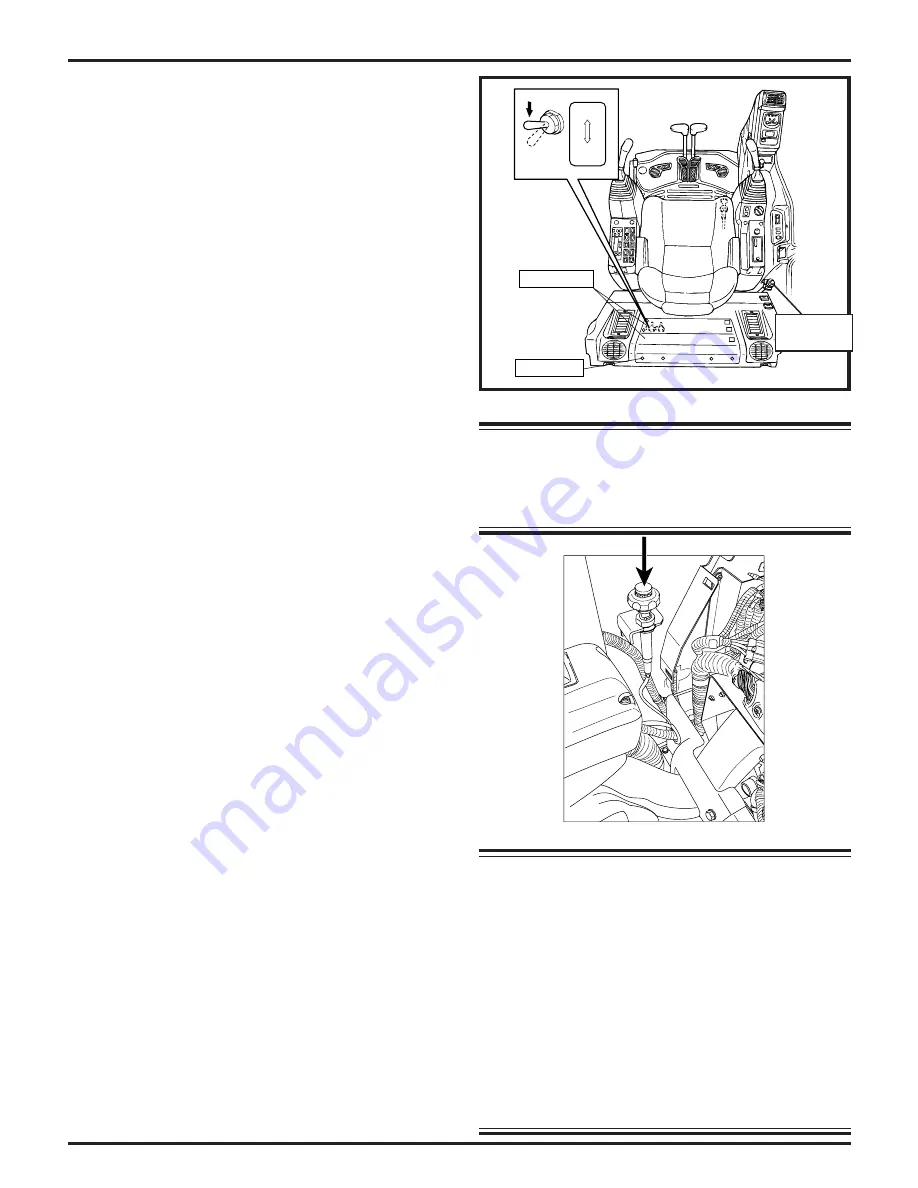

3. Installation of Manual Throttle Cable

SK160 through SK330 (pre-M/C) Only.

If the stepping motor is damaged or has lost

communication to the CPU, it is possible to have

manually control of the diesel injection pump from

the operators cab.

1.

Stop the engine.

a. Go to the engine compartment

b. Remove the linkage between the stepping

motor and injection pump.

c.

Install the manual throttle cable which is

standard on most Dynamic Acera

excavators.

(Pre M/C Only)

See FIGURE

3.32.c.

d. if computer has failed the the KPSS

Switch must be changed to the release

position, if only the stepping motor has fail

leave the switch in the KPSS position.(see

kpss switch adjustment below for this

adjustment.)

4. KPSS Release Mode.

a. Remove the covers for the control panel

located behind the operator ’s seat:

b.

Locate the switches for the KPSS release

and the swing parking brake release and

flip them to their release position.

c.

Install rear panel covers.

d.

Start the engine.

e.

Press the button at the center of the manual

throttle knob and simultaneously pull the

cable control to raise the engine speed to

high idle condition.

FIGURE 3.33.a

Figure 3.33.b.

NOTE

If the mechanical throttle is used when the KPSS

system has no problem, then the stepping motor

may be damaged as well and the main C-1 Con-

troller and the machine ’s performance will be very

erratic. The error code 31 will show on the panel

and the machine will not shut down through the

ignition key. Set the ignition key to the OFF posi-

tion and pull the engine emergency stop control

to shut off the engine. Make sure the mechanical

throttle is disengaged before restarting the ma-

chine.

NOTE

Manual throttle control cable is not present on

the SK480 Dynamic Acera with Mitsubishi

6D24-TLAB

SK32002025

KPSS

RELEASE

REAR PANEL

SET SCREW

Not present

on SK480