1.

Release catch of bonnet, open engine hood

on the rear side of machine and lock it

with stay.

2.

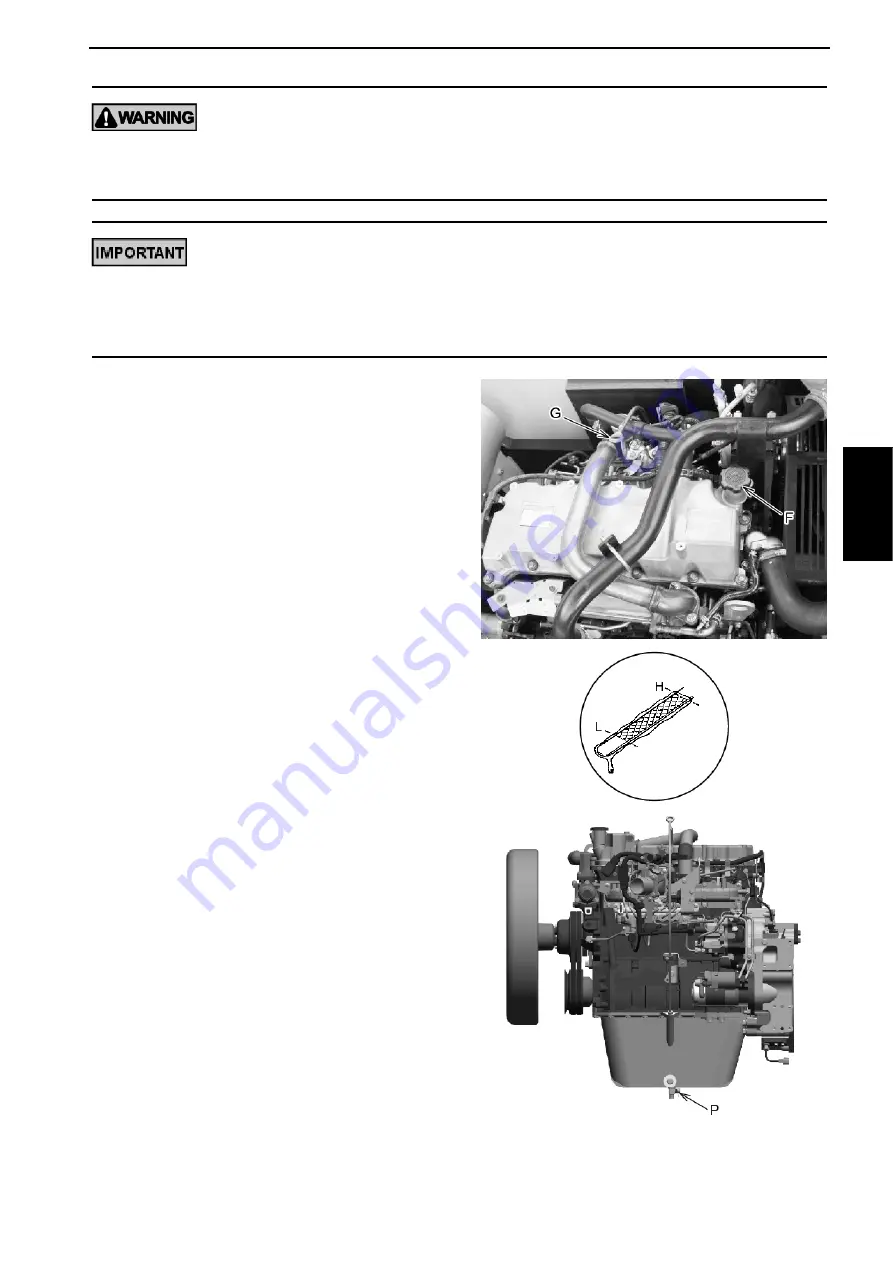

Pull out oil level gauge (G) and wipe oil

with a clean cloth.

3.

Insert oil level gauge (G) in oil pan fully.

4.

When the level is in the range of H - L of

oil level gauge (G) it is proper. If the level

is insufficient for L level, make up engine

oil for the shortage through oil filler cap (F).

If the oil is contaminated and deteriorated,

change it ahead of schedule without

depending on the periodic change interval.

For oil in use, refer to "4.3 LUBRICANT,

FUEL & COOLANT SPECIFICATIONS" in

Chapter 4.

5.

When oil level is higher than H level,

connect drain hose (H) to engine drain plug

(P), and drain excess engine oil. And be

sure to check oil level again.

6.

If the oil level is proper, insert level gauge

(G) securely, close engine hood and lock

it with starter key.

3

B. Checking Oil Level of Engine Oil Pan and Making Up

Immediately after engine is stopped, there is a possibility of getting burn with heated parts and oil.

Start working after the temperature is not hot.

-Make sure the machine is on firm level when checking engine oil level.

-Always make sure to check engine oil level before starting the engine.

-Keep the engine to standstill for at least 30 minutes, when checking engine oil level after working.

[

3. MACHINE OPERATION

]

3-5

Copyright © 2015 Kobelco Construction Machinery Co.,Ltd. All rights reserved. [S2YF00022ZE01] [0731CsCshWbYs]