1.

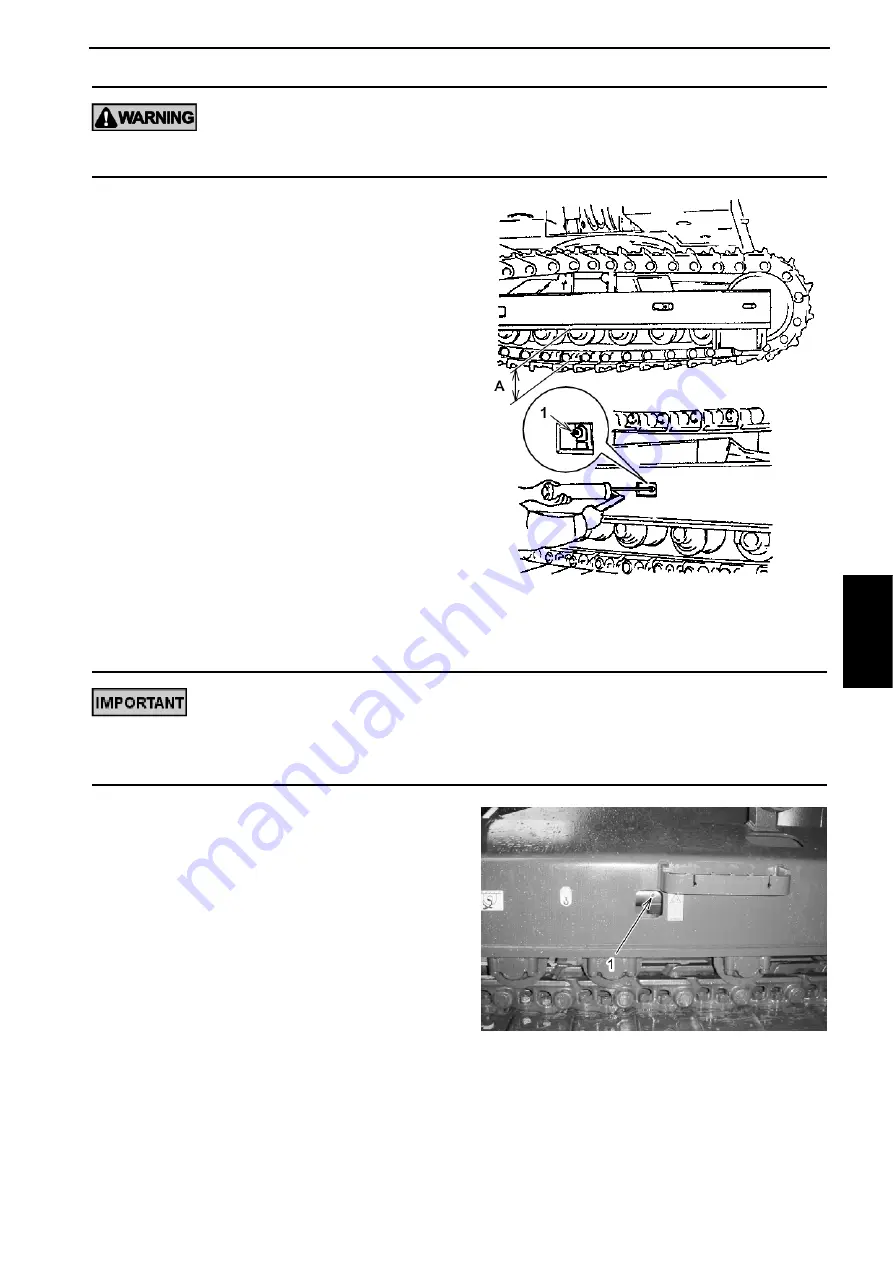

Operate swing, arm, bucket and boom controls

until machine is set up as shown in.

2.

In center of track, measure the distance

between the bottom of frame rails and surface

of shoe.

3.

Perform steps 1 and 2 on right track.

4.

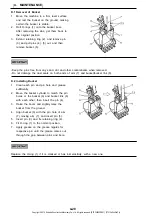

To increase track tension, set machine as

shown in figure and with grease gun inject

extreme pressure No.2 grease into idler

adjustment grease nipple (1) until proper tension

is reached. Perform this procedure on both

tracks.

Slack:

Proper Tension (A): 320 to 350 mm (12.6 to

13.8 inches)

5.

To decrease track tension, set machine up as

shown in figure.

6.

Carefully loosen the adjusting grease nipple (1)

to allow grease to escape.

7.

Tighten grease nipple (1), measure track tension

as shown in figure.

Tightening torque: 49 to 69 N-m (36.6 to 51.4

lbf-ft)

8.

If necessary, perform steps 5 through 7 on

other track.

4

C.

Track Tension

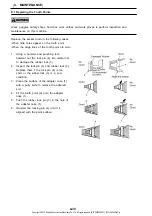

Support lower frame with suitable blocks.

After injecting grease, operate the travel control forward and reverse for the track being adjusted. This

will balance the tension between the idler and the sprocket. Then remeasure as shown in figure.

[

4. MAINTENANCE

]

4-39

Copyright © 2015 Kobelco Construction Machinery Co.,Ltd. All rights reserved. [S2YF00022ZE01] [0731CsCshWbYs]