8

5

Air tools require lubrication throughout the life of the tool otherwise moisture in the compressed air will rust the

air motor. Correct lubrication is vital for the maximum performance of the air tool and an airline lubricator

should be fitted into the system down stream of the filter. Failure to lubricate the tool at the air inlet will void

your warranty.

Either use an air line lubricator with air tool oil adjusted to two drops per

minute, or if an air line lubricator cannot be used, add a teaspoon of air

motor oil to the inlet or into the hose at the nearest connection to the air

supply once a day and then run the tool (See fig. 1). ISO Grade VG22 oil is

recommended. A rust inhibitive oil is acceptable for air tools.

Any excess oil in the motor is expelled immediately from the exhaust port.

Always direct the exhaust port away from people or objects.

Do not lubricate the tool with flammable or volatile liquids such as paraffin (kerosene), diesel or jet fuel.

Fig. 1

DUST COLLECTION

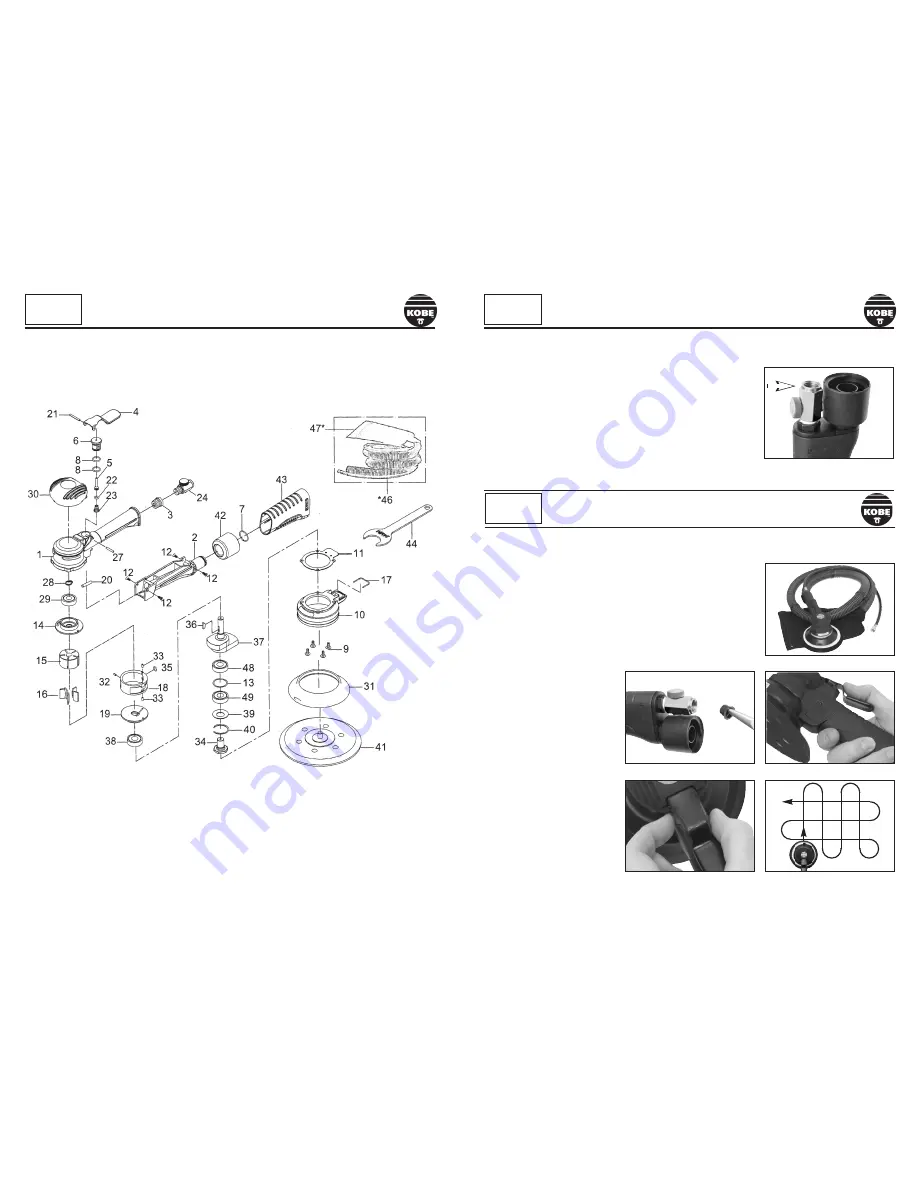

Always wear a protective dust mask in addition to using a dust extraction hose.

The Orbital Sander generates its own vacuum. Kobe Tools thoroughly

recommends that the Orbital Sander is connected to a Portable Dust

Collection System (See fig. 2) which is sold separately (See page 6) or

connected to a central vacuuming system.

OPERATION

Remove foreign objects such as nails and screws from the work piece

before commencing sanding.

1.

Carry out daily inspection and lubrication of the tool.

2.

Remove the plastic dust cap using a pair of pliers (See fig. 3).

3.

The amount the throttle lever is pressed down, will determine the

speed of the tool (See fig. 4).

4.

Adjust the power regulator on

the top of the Orbital Sander

by turning it in either direction

(See fig. 5).

5.

To get an even finish, move

the Orbital Sander up and

down and then change the

direction from left to right

(See fig. 6).

6.

To avoid unwanted swirl

marks, place the Orbital

Sander on the material and

then switch it on. When

finished sanding, remove the

Orbital Sander and then switch

it off.

7.

Beware of the tool running on

for some time after the throttle

lever is released.

Fig. 4

Fig. 5

Fig. 3

Fig. 6

Fig. 2

KOBE

I N D U S T R I A L

AIR TOOLS

SPARE PARTS BREAKDOWN

KOBE

I N D U S T R I A L

AIR TOOLS

LUBRICATION

FSO150

Version: March 2011

Continued on page 6

Continued on page 9

KOBE

I N D U S T R I A L

AIR TOOLS

OPERATION