USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

REV. 01.07.2019

19 din 37

- Adjust the pump operation (5, 6 or 7m) depending on the installation (see chapters 8.3 and 11.3);

- continue to fill the system, with the ventilation function switched on up to

1.1-1.5 bar

;

- check the tightness of the entire system. If there are losses, the problems must be remedied;

In the case of plants equipped with automatic ventilation: keep the pump on until noises are heard in the installation;

In the case of plants without automatic ventilators: manually operate the manual air vent to remove the air from the main

exchanger until noises are heard in the installation;

- heat the radiators;

- Make 2-3 cycles of 50-60 seconds of air-venting, following the steps described above;

- check the system pressure indicated on the display. If necessary, fill with thermal agent following the above steps.

- Remove the flexible hose.

If necessary, fill with thermal agent following the above steps.

Caution! Obligatory operation!

Check the correct functioning of the pump with no fuel in the central heating BOILER.

Functioning of the central heating BOILER with a blocked pump can lead to complete damage of the main heating

switch.

Caution! Obligatory operation!

Incorrect airing of the installation can cause damage of the main heating switch.

Note!

Recommended pressure on the thermal circuit is 1.5 bars.

The following operations are executed to empty the installation:

Emptying is done by means of the emptying tap of the central heating BOILER.

The emptying points must be located in accessible places so as to allow the water to be drained.

Caution!!

Danger of hot water burns when emptying the BOILER.

6

Operation instructions

6.1

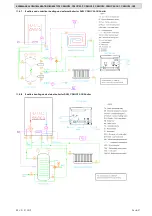

Control Panel LMC1X for boiler types C38GC25, C38GC29, C38GC35

The LMC1X control panel (fig.1.9) equipes the boiler types

C38GC25, C38GC29, C38GC35.

The LMC1X control panel (fig.1.9) allows the visualization and change of parameters defining the functioning of the central

heating BOILER. It consists of:

-

10 switches (J1÷J8, J10, J11) - tab.3;

-

LCD display, where communication messages (graphic symbols) are displayed. The meaning of the 15 types of symbols is

presented in table 4.

Fig. 1.9 Functions of keys on the control panel

Table 3: Control panel keys

Key

Note

Description:

J1

P-

Used to navigate in the menu: it will select the previous parameter

J2

P+

Used to navigate in the menu: it will select the next parameter

J3

+

Used to increase the value of the active parameter (selected)

J4

-

Used to decrease the value of the active parameter (selected)

J5

MENU/OK

Used to enter the menu

Enable / disable function central vent (long press in stand-by mode)

J6

POWER

Used to turn ON / OFF power

J7

Used to change the mode winter / summer

J8

RESET

Used to reset the command and control electronic board from a state of error

J10

i

bar

Used to control (display) the boiler pressure (inhibited function for this model)

J11

LIGHT

Used to activate / deactivate the backlight

Fig. 1.9 LMC1X control panel