Overview

October 2020

1-3

Printer Supplies

Go to

www.kodakalaris.com/go/printerupdates

for information on

ordering supplies.

Paper and Ribbon

Paper and ribbon are sold separately.

IMPORTANT:

For best results, replace the paper and ribbon at the

same time. Used ribbon is safe for land-fill disposal. Do

not recycle used ribbon.

* The paper roll contains a small amount of additional paper to

allow for the extra feed when loading the paper.

** Paper and ribbon rolls contain material to make the stated print

quantity. Actual number of prints will vary depending on mix of

6 x 8 in. and 4 x 6 in. prints produced.

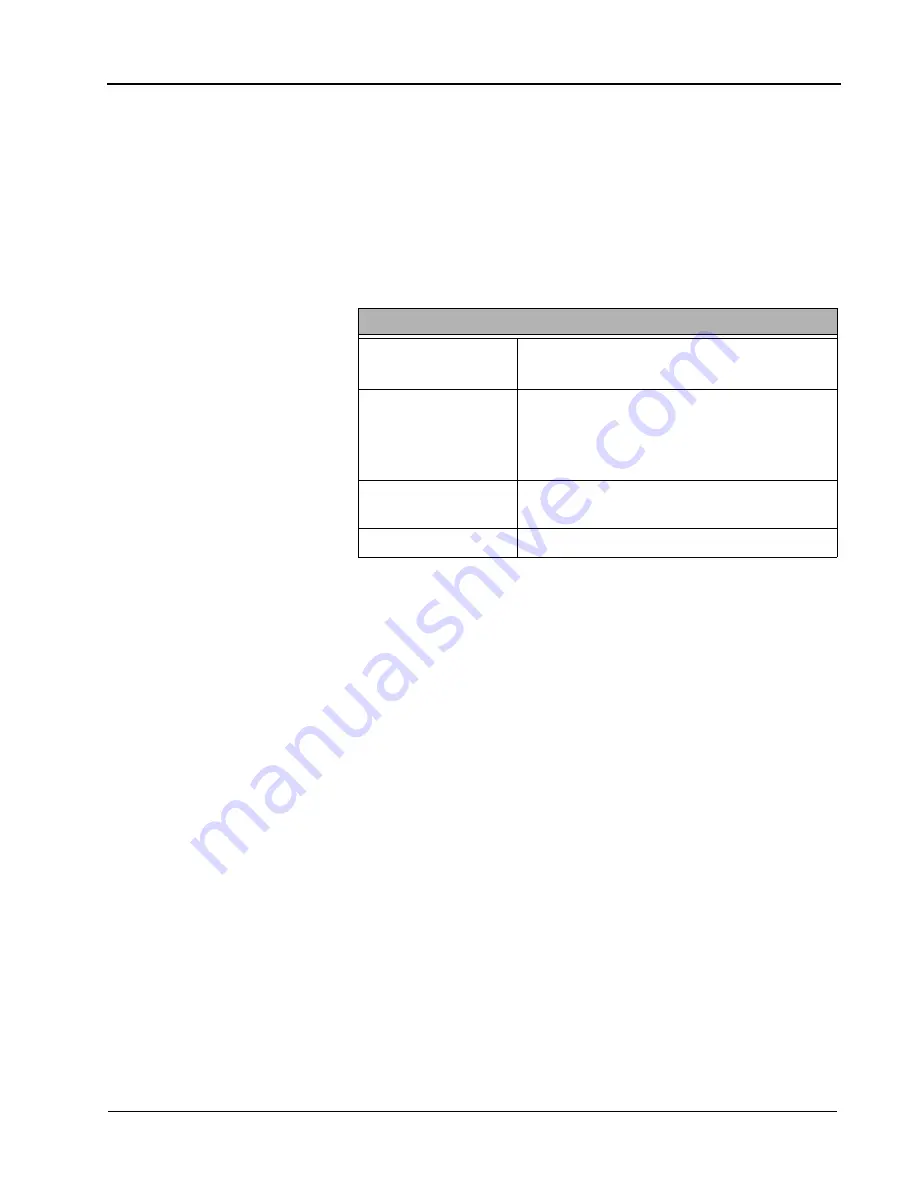

KODAK Photo Print Kit 6900 / 6800 / 6R Specifications

Storage

specifications

40-85° F (5-30° C)

60% relative humidity or lower

Capacity*

750 - 4 x 6 in. (10 x 15 cm) prints, paper, and

ribbon** or

375 - 6 x 8 in.(15 x 20.3 cm) prints, paper, and

ribbon**

Paper and ribbon

width

6 in. (15 cm)

Ribbon patch length

8 in. (20.3 cm)