Getting Started

1–3

January 1998

Finding a Location

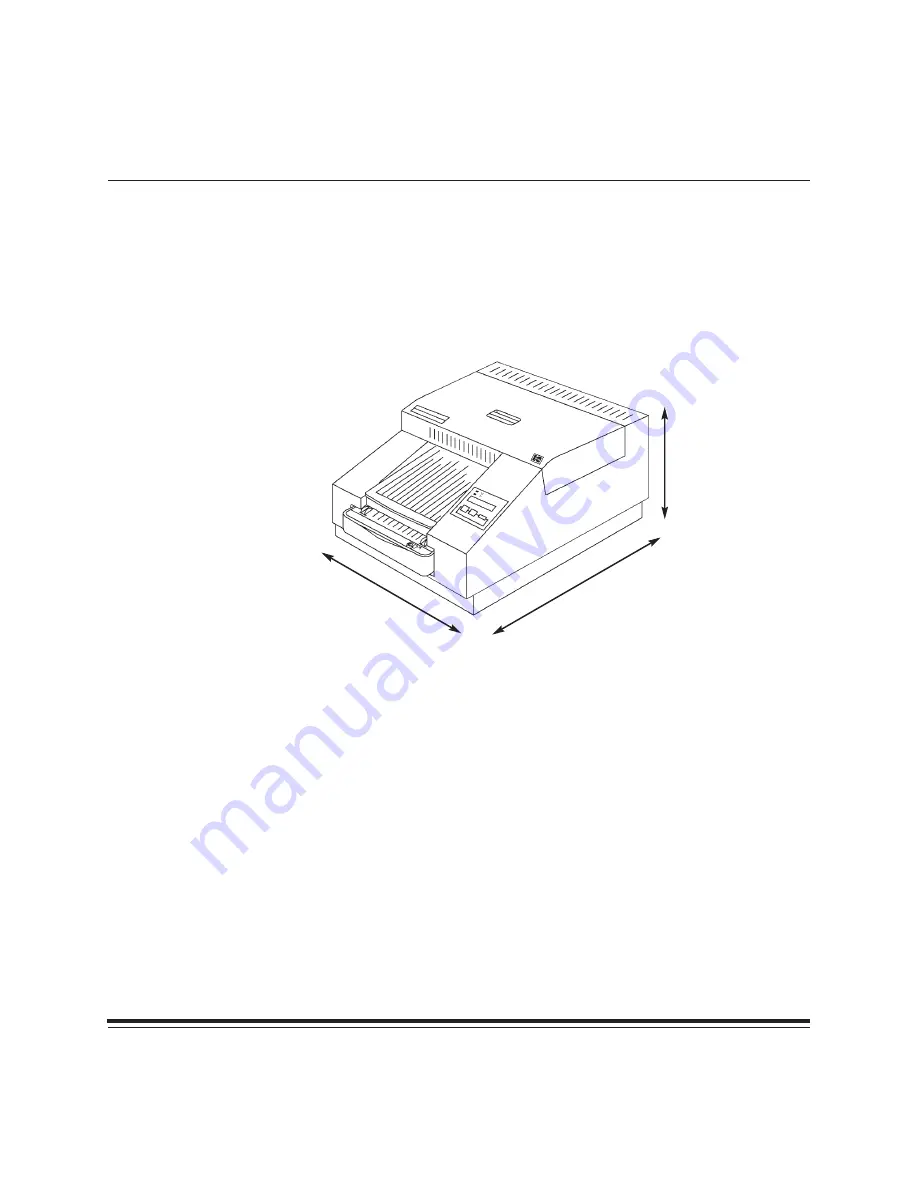

As you determine the best location for the 8657 Printer, be aware

that certain connections and operations require access behind and on

the side of the printer. You should place the printer so that air flow is not

blocked. The following diagram illustrates the necessary space

requirements.

17

I

12

I

(plan for 20

1

/

4

I

to allow room for

opening cover)

24

I

(plan for 37

1

/

2

I

to allow room for

removing tray)

Airborne dirt particles can cause image quality problems. Avoid placing

the printer in areas where ventilation ducts, open doors, or frequent

passers-by might expose the printer and paper to high levels of debris.

NOTE: Allow two (2) inches (about 5 cm) on all sides of the printer for

easy access.

Refer to Appendix A,

Printer Specifications, for more information about

site requirements.