5

Hazards

The major hazards associated with the platesetter are laser radiation,

moving mechanical parts, and hazardous voltage electrical parts.

Laser hazards

The platesetter has safeguards that reduce the risk of injury from laser

hazards.

Model MTA devices have one of the following thermal imaging heads:

TH2, TH3, TH6 or TH7.

The thermal imaging head has two lasers, which emit visible and

invisible high-powered laser radiation:

●

Visible (red) focus laser (Class 3b, approximately 660-680 nm)

●

Invisible (infrared) write laser (Class 4, approximately 808-830 nm)

Laser emissions from a thermal imaging head are invisible to the naked

eye and are very dangerous if they contact skin or eyes.

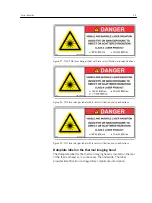

DANGER: Follow these guidelines to reduce the risk of exposing everyone in the

vicinity of the platesetter to laser radiation (directly from the laser system or from

the laser reflected on shiny or matte surfaces):

●

Do not operate the platesetter if you suspect that any part of the laser system

is defective.

●

Do not tamper with the interlock system on the access panels or the doors.

●

Do not attempt to open or to remove doors or panels while the platesetter is

exposing media.

●

Do not attempt to operate the platesetter with any doors or panels open.

●

Do not look directly or indirectly into the laser beam.

The thermal imaging head emits both visible and invisible high-powered laser

radiation as part of its normal imaging process. Even brief exposure to either type

of laser radiation can burn skin and can cause permanent degradation or loss of

eyesight. In the presence of flammable material, the laser beam is also a fire

hazard.

The platesetter is a Class 1 laser product. This means that if you comply

with the information in this guide, the platesetter's safety mechanisms

reduce the risk of harm from visible and invisible high-powered laser

radiation. The Class 1 laser product label, located below the power

switch at the rear of the platesetter, indicates compliance with

standards for laser safety.

Summary of Contents for Magnus VLF Q2400

Page 2: ......

Page 4: ......

Page 6: ...vi Magnus VLF Q2400 Q3600 Platesetter Safety Guide for Operators ...

Page 14: ...8 Chapter 1 Introduction to safety information ...

Page 22: ...16 Chapter 2 Safe operation ...

Page 26: ...20 Chapter 3 Safe maintenance ...

Page 45: ...Figure 49 High touch current label Electrical hazards 39 ...

Page 46: ...40 Chapter 5 Hazards ...

Page 47: ......