NovaJet 800 Series Training Guide

35

Technical Bulletin 2

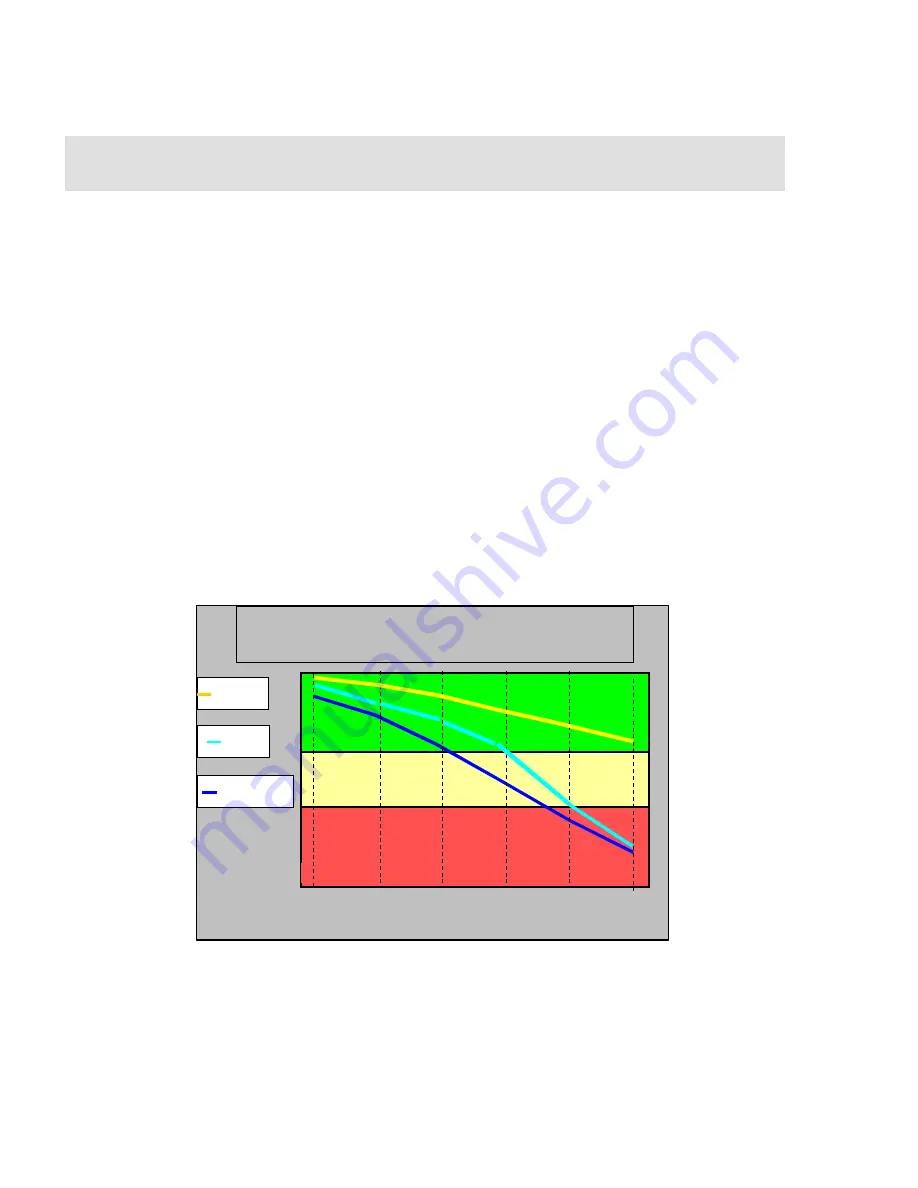

Dry Time Guidelines - Printer in Auto Take-up Mode

The NovaJet 800/KODAK 4800 series printers are considered some of the fastest

inkjet printers in the market. Consequently, certain images, using high-speed pass

settings, may not have enough time to dry before being automatically rolled up on

the take-up assembly. This is usually determined by the ink lay down percentage.

Though a typical image would only use 150% ink lay down, some images that use

more ink may require a slower print speed to use the auto take-up feature. The

following chart is intended as a general guideline to monitor the output or indicate

precautionary measures should be taken. Your results will vary depending upon

environmental conditions, ink loading, media, and printer settings.

Example of results for KODAK Production Photographic Glossy Paper with 200% ink

load:

The printer is set to Photo Mode (

2x4 cartridge set, 3-pass print mode @ speed 10

)

with the

Dryer

ON – Heat setting of 100%.

Printing using GS+ ink at 200% ink lay

down, the GS+ line (the blue line) is passing through red area of the chart. This

indicates there will not be enough time to completely dry the print before reaching

the Automatic Take-up. Precautionary measures should be taken to insure that the

image would not be damaged. Usually this would simply require selecting a

slower print speed at the printer (If you are not familiar with this feature, please

refer to the User Guide CD to select print speeds. Also refer to

Print Mode

Comparisons

at the end of this document for real world printing

operations/applications)

NOTE:

These recommendations are based upon printing in conditions of 50% to 65% relative

humidity (RH) and at ambient temperature (72° F, 22° C). You may experience different results if

your temperature and humidity values are different. If your RH is less than 50%, you can expect

much faster dry times. If your RH is greater than 65%, your dry times will normally be longer.

The above chart is intended as a general guideline.

% Ink Lay Down

GS PLUS

GX

GO

GO

Images may not be able to use full speed take-up

10

0%

-

12

5%

-

15

0%

-

17

5%

-

20

0%

-

22

5%

-

Take-up may be used at full speed

Most images may use take-up at full speed

Take-up & Dry Time

50% to 65% Relative Humidity, 22 deg C (77F)