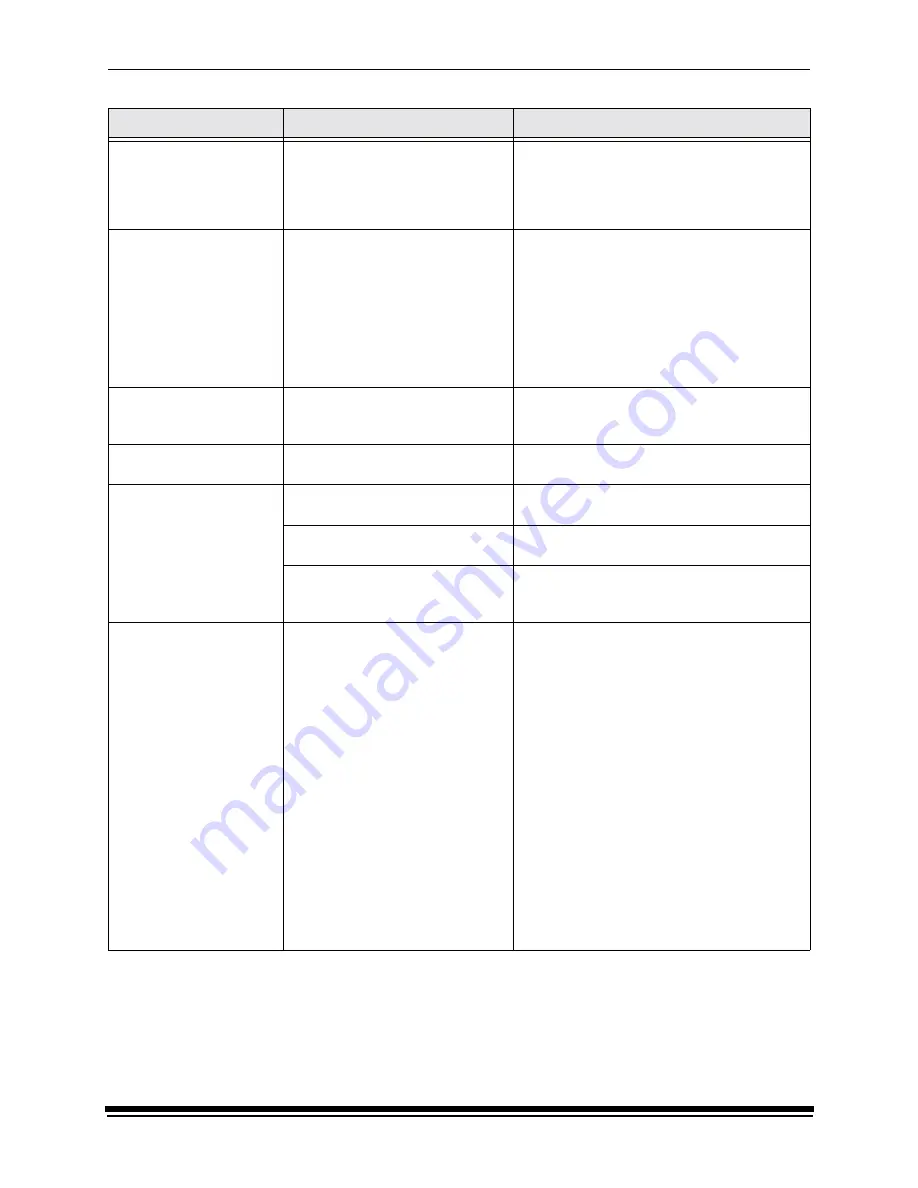

Diagnostics and Troubleshooting

October 2002

5-13

The vacuum reduction

insert is damaged and

causing noise in the printer.

• The vacuum reduction insert was

not installed properly and has

become damaged.

• A damaged vacuum reduction

insert was installed.

Properly install an undamaged vacuum

reduction insert.

The paper is being creased

and crumpled when

feeding into the printer.

The lead edge of the paper has not

been squarely trimmed and is being

pulled at an angle or unevenly or it is

being loaded at an angle into the

rollers.

1. Pull the paper out of the printer from the

paper supply area.

2. Recut the lead edge of the paper squarely.

3. Reload the paper. Wait for a message and

then push the paper evenly and slowly.

NOTE:

If necessary, remove the curl in the

paper by rolling the paper on an empty

core in the opposite direction of the

curl.

The paper jams repeatedly.

Small strips or pieces of paper are

caught in the printer from the

previous paper jam.

Remove small pieces of paper from the printer.

The prints have not been

cut correctly.

Strips of paper are caught in the

knife area.

Remove the strips of paper from the knife area.

The borders on the prints

are not the right size.

The slug width is not correctly set.

Reset the slug width, see “Selecting the Slug

Width for the Paper” on page 3-18.

The host software’s image

positioning is not correct.

Refer to the instructions for the host software.

The page start parameter may be

incorrect.

See the information for “Page Starts” in

the“Setting the Page Starts Value” on

page 3-19.

The edge(s) of the prints

are damaged and the

image is skewed.

• The paper is not loaded correctly

in the paper cassette.

• The paper cassette clamp is not

secured correctly.

• The paper cassette was not

aligned with the pin when

installed on the shelf.

• The paper cassette was not

picked up or carried correctly and

the paper has “telescoped”.

1. Reload the paper in the paper cassette.

2. Position the paper cassette on the pin of the

shelf.

3. Close the cassette clamp to lock the paper

cassette into position.

NOTE:

Always carry the paper cassette with

two hands to prevent the paper from

sliding to one end or “telescoping”.

4. When loading paper into the printer:

• cut the corners of the lead edges of the

paper at a 45

o

angle

• wait for a message to feed

• push the paper slowly into the printer’s

rollers, keeping the paper taut between

the cassette and the rollers.

NOTE:

Push the paper evenly so that the

paper remains flat and does not buckle

and do not push the paper too hard

against the paper alignment guide.

Observation

Possible Cause

Possible Solution

Summary of Contents for Professional RP 50

Page 1: ...KODAK PROFESSIONAL RP 50 LED Printer Operator s Guide Part No 2J0686 ...

Page 16: ......

Page 74: ......

Page 90: ......

Page 118: ......

Page 122: ......

Page 146: ...Additional Calibration Information C 12 October 2002 Value Graph ...

Page 147: ...Additional Calibration Information October 2002 C 13 Difference Graph ...

Page 168: ......

Page 190: ......

Page 197: ......