Preface

MDC-7000/7900 Series

2

0092669002-07

Precautions for maintenance

• Caution against residual high voltage:

Capacitors used in the Display unit and the modulator circuit of the transmission unit may keep high

voltage for several minutes even after turning off power. The maintenance and inspection of this part

should be performed at least 5 minutes after powering off or applying the appropriate measure to

discharge the residual electrical charge.

• Keep inboard power source “Off”:

An electric shock is possible if the power switch is accidentally turned on during the maintenance

operation. In order to prevent such an occurrence, please ensure to disconnect the power breaker of

the onboard power source and the device. Furthermore, it is recommended to post the word-of-caution

tag shown to be in a "working state" near the power switch of the device.

• Caution against the dust:

Dust can temporarily cause distress to the respiratory system. Take care not to inhale dust when

cleaning the interior of the device. It is recommended you wear a safety mask.

• Measures against static electricity:

Static electricity occurring from carpet on the floor of the cabin, clothes made of synthetic fiber etc., may

damage some electronic parts on the printed circuit board. Please work on the printed circuit board only

after taking measures against static electricity.

• Prohibited matter:

Any Display and Scanner unit combination other than specified in the manual is prohibited and will void

manufacturer’s warranty.

• Break in procedure of stored radar:

Following procedure is recommended for “Break In” of the stored radar.

Otherwise the radar sometimes exhibits unstable transmitting operation such as arcing at its initial

operation after long period of storage and make the operation more difficult.

1. Extend preheat time as long as possible (preferably 20 to 30 minutes).

2. Set the pulse width to the shortest one and start the operation.

When the operation in the shortest pulse is stable then go to operation in longer pulse and repeat

the similar step until the operation reaches to the final pulse condition.

Summary of Contents for MDC-7006

Page 1: ......

Page 2: ......

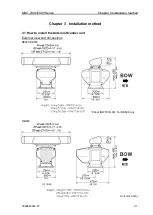

Page 44: ...Chapter 3 installation method MDC 7000 7900 Series 3 24 0092669002 07 Unit mm inch MRM 108 ...

Page 96: ... This page intentionally left blank ...

Page 134: ... This page intentionally left blank ...

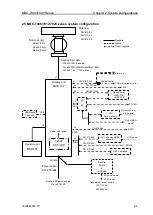

Page 155: ...0092669002 07 A 1 INTER CONNECTION DIAGRAM RB807 ...

Page 156: ...A 2 0092669002 07 INTER CONNECTION DIAGRAM RB808 ...

Page 157: ...0092669002 07 A 3 INTER CONNECTION DIAGRAM RB809 ...

Page 158: ...A 4 0092669002 07 INTER CONNECTION DIAGRAM MRD 108 MRO 108 ...

Page 159: ...0092669002 07 A 5 INTER CONNECTION DIAGRAM MRM 108 MRO 108 ...

Page 160: ......