Page 27

Version 02-2012

Operation

Compact-Light

The

Compact-Light stops moving when twist-grip is in the 0 position (see fig. 8 – page

22) or when the clutch/safety stop lever (engine drive) is released – the hydraulic traction drive is

interrupted.

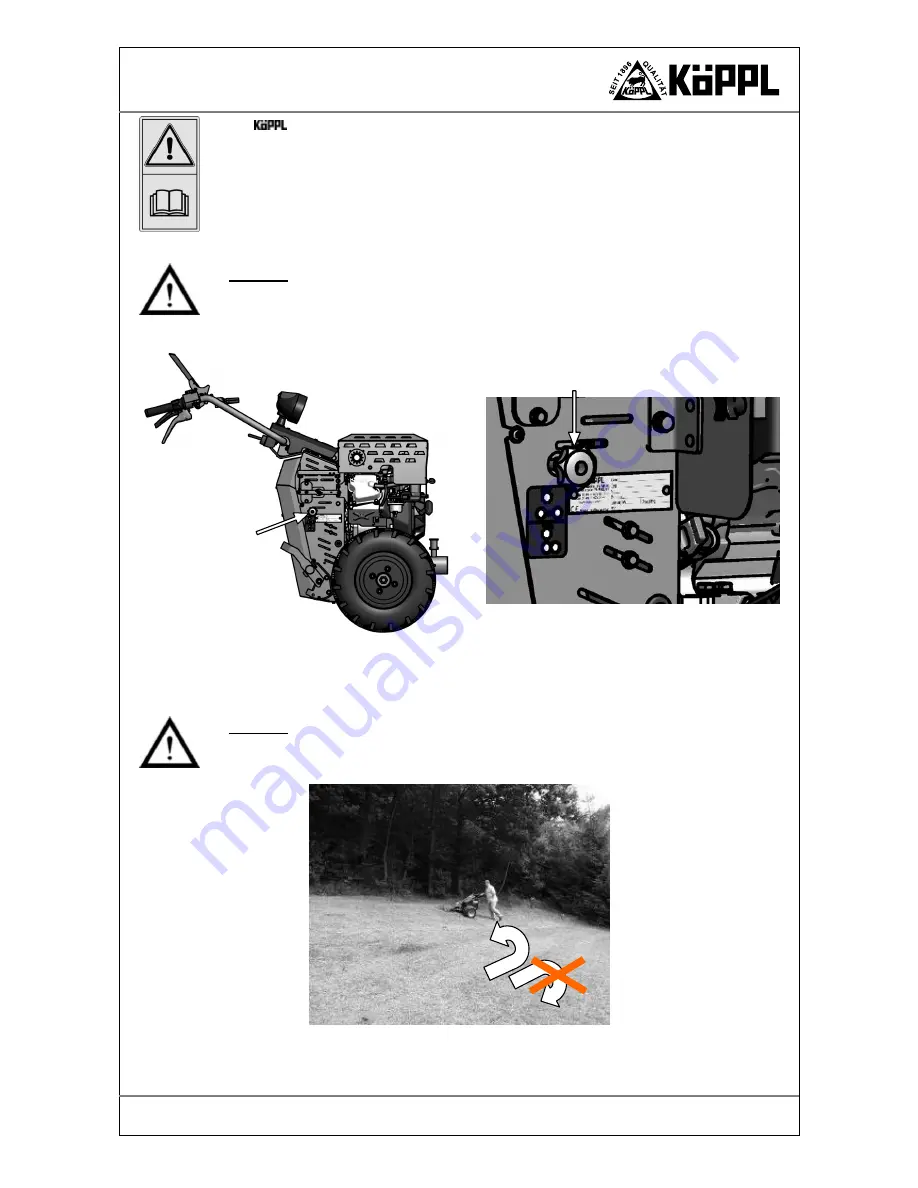

In case of failure of the hydraulics or the engine, the appliance can be pushed by opening the

locking valve. The locking valve is located on the left on the chassis.

Turn the unlocking screw anticlockwise to open the valve – pushing operation.

Turn the unlocking screw clockwise to close the valve – normal operation.

Caution!

Note that the appliance can run away uncontrolled on a slope if the locking valve is open! Check

during operation that the unlocking screw is closed, otherwise there is a danger of the hydraulic

system overheating, which can result in damage to the hydraulic system!

Working with attached devices on a slope

Caution!

When working on a slope, bear in mind that you may only turn in an uphill direction!

Pull the appropriate lever.

Fig. 15. Turning on a slope.

Unlocking screw

Fig. 14. Unlocking screw.

Unlocking screw