!

5

•

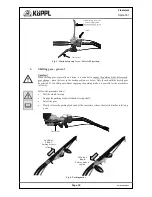

Never work on the attached device when the engine is running; switch the engine off in or-

der to carry out such work.

•

Observe the generally applicable regulations for safety and the prevention of accidents in

addition to the instructions in this operating manual.

•

The mating surfaces of the rapid-change flange on the basic device and on the attached de-

vice must be clean; they must be cleaned if necessary.

•

The mating surfaces must be greased with special long-life grease (see appendix).

•

Secure the

2-wheel tractor and the attached devices against rolling away (parking

brake, wheel chocks). Attach the transport lock and safety device and place them in the pro-

tective position.

•

There are crushing and cutting zones on externally powered parts (e.g. hydraulics).

•

Only work if the light and visibility conditions are good.

•

The

2-wheel tractor may not be driven (operated) in 4th gear if a sulky is in use!

14.

Brakes

•

Check the function of the brakes – if they exist – each time before driving!

•

The brake system must be subjected to regular thorough checks.

•

Adjustments and repairs to the brake system may be carried out only by specialist work-

shops or recognised brake service companies.

15.

Engine

•

Do not leave the engine running in a closed room – danger of poisoning!

•

Always switch the ignition off when turning the engine off!

•

Never transport the engine with the fuel tank or the fuel tap open.

Refer also to the motor

manufacturer’s operating manual!

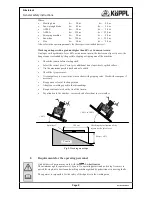

16.

Tyres, screwed connections

•

When working on the wheels, ensure that the tractor is parked safely and secured against

rolling away!

•

Repairs to the tyres may be carried out by specialists using suitable mounting tools!

•

There is a risk of explosion if the tyres are over-inflated!

•

Check the tyre pressures regularly!