Step 5: Shaft, Seesaw & Arm Installation

Arms:

•

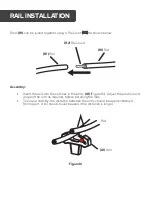

To secure the Arm assembly to the shafts, insert the shaft into Arm Stand B

(A4)

.

•

Secure the shaft in place by inserting an Arm Wrench

(A5)

and rotating 90°

counter-clockwise (Figure 12).

Attaching the Arms & Seesaws to the Shafts:

Attach the Arm assemblies (A1) and Seesaws

(FI)

to the Shafts

(S1) (S2)

. Pay close attention

to the orientation of the Arms & Seesaws (Figure 13).

Note:

B & C are 200mm Shafts

(S2)

. The 2 Seesaws

(F1)

on C are both Left Turn Seesaws.

(A5)

Arm Wrench

(A4)

Arm Stand B

Figure 12

Note:

Unlock the Arm Wrench before adjusting the arm angle.

UP

DOWN

BACK

FRONT

Summary of Contents for KASPCRLGLWB

Page 1: ...DIY MARBLE RUN ROLLER COASTER KASPCRLGLWB...

Page 2: ......

Page 22: ...Elevator Entry Continued from previous image Figure 28 Loop...

Page 25: ...REFERENCE IMAGES...

Page 26: ...NOTES...

Page 27: ......