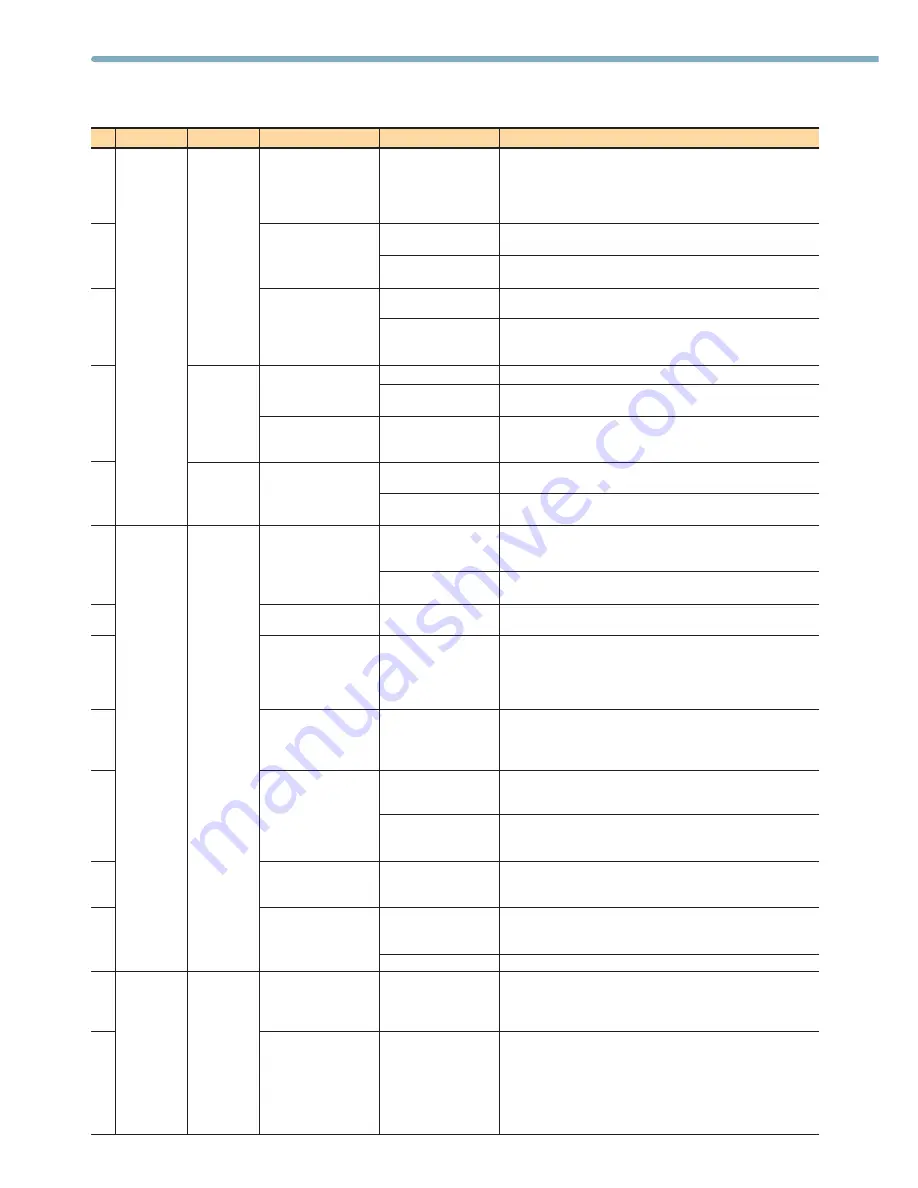

34

No. Category

①

Category

②

Symptom of problem

Probable cause

Solution

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Ionizer

Electrostatic

potential

sensor

Cleanliness

monitor

Common

Blow type

Fan type

EP sensor

CC monitor

(main unit)

LED fails to light even

after power is switched

on. Or it lights

momentarily and then

goes out again.

Red LED (alarm)

lights up.

Ion balance collapses.

Red LED (alarm)

lights up.

No air is being delivered.

LED fails to light even after

power is switched on. Or it

lights momentarily and then

goes out again.

Measurement of GND

does not approach 0V.

LED (red) is lit up.

EP monitor and support

software display values

differ from the actual

charge amounts.

LED (red) fails to blink

even when threshold

value is exceeded.

LED (red) blinking cannot

be reset.

Nothing happens even

after setting the EP

sensor (SET2).

“PEr” display appears on

the monitor.

Power does not switch on.

Power is switched on and

display appears, but then

the LEDs also light up

one by one.

①

No power being

supplied.

①

Discharging needle

dirty or damaged.

②

Discharging needle not

firmly attached.

①

Discharging needle

dirty.

②

Ground not connected.

①

Loose metal cap.

②

Nozzle in contact with

the grounding body.

①

Ionizer throttle valve

too tightly squeezed, or

a piping error.

①

Power switch OFF.

②

Safety circuit activated.

①

Ground not connected.

②

Ground being affected by

nearby charged objects.

①

EP sensor abnormality.

①

EP sensor or EP monitor

measurement distance

settings different from the

actual measurement

distance.

①

Voltage comparison

output valid/invalid

setting invalid.

①

Electric potential in

excess of the set

threshold value detected.

②

Reset cannot be performed

from EP monitor and

support software.

①

“SEnd” not sent after

setting input value.

①

EP sensor abnormality.

② Wiring error.

①

Power cable

disconnected. No

power being supplied.

① Measurement

preparation time.

・

Check that the DC power switch is turned ON. If using an AC adaptor,

check that it is firmly plugged into the electrical outlet.

・

Check that the voltage applied is within product specifications range.

・

Check whether the power and signal cables have breaks.

・

Check that the power and signal cable wiring is correct.

・

Check the tips of all of the discharging needles, and clean the dirty

tips, or replace the damaged ones.

・

Check that the discharging needle (discharging needle unit) is firmly

attached.

・

Check whether the discharging needle is dirty.

・

Check that the ground wire is firmly connected to the ground terminal

on the main body.

・

Check that the ground wire is firmly connected to the ground.

・

Check whether the metal cap is loose.

・

Check whether the metal cap, nozzle, or pipe is in contact with the

grounding body.

・

Check whether the air is throttled too much.

・

Check whether air is being supplied to the ionizer.

・

Check the pneumatic circuit.

・

Check that the switch is ON.

・

Check that the louver (DTRY-ELF series) and discharging needle unit

(DTRY-ELW series) are both firmly set.

・

Check that the ground wire is firmly connected to the ground terminal

on the main body.

・

Check that the ground wire is firmly connected to the ground.

・

Check whether there are charged objects nearby.

・

Repairs required. Consult with Koganei.

・

Check the measurement distance settings and actual measurement

distance.

The check methods are as follows.

・

In the support software, check that the Enabling voltage setting range

was selected in the checkbox.

・

Check that the EP monitor EP sensor setting (SET2) is set to CPE0.

・

Check that the electric potential is lower than the threshold value, and

then reset.

・

Check that the communication cable is connected.

・

After inputting the setting value, send “SEnd”.

・

Check the EP sensor’s alarm LED. If it is lit, it means an EP sensor

abnormality, and that the EP sensor requires repairs. Consult with

Koganei.

・

Check that the wiring is correct.

・

Check that the AC adaptor is firmly plugged into the electrical outlet.

・

Check that the voltage applied is within product specifications range.

・

Check that the AC adaptor plug is firmly inserted into the power

supply jack.

・

This is a normal operation. Since the sampling time for this product is

5 minutes, the first 5 minutes after switching on the power is required

as preparation time. During the preparation time, the level display bar

lights up in the sequence of red blinking

→

orange blinking

→

green

blinking

→

red lit up

→

orange lit up

→

green lit up, to show that

preparation time is in progress. After 5 minutes have elapsed,

measurement starts.

Troubleshooting