3

●

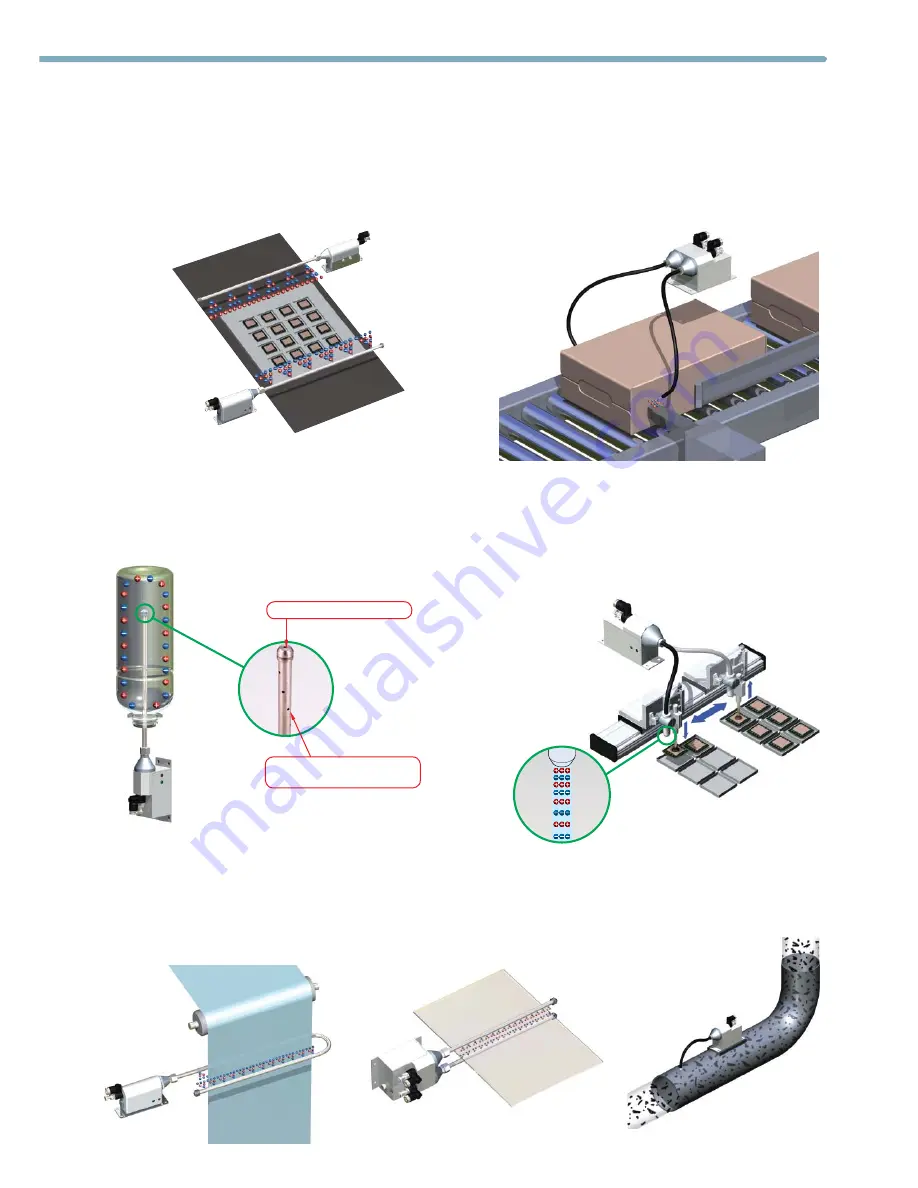

Removal of static charges in printing

process

Use 2-head type Ionizers with bender nozzles. Prevents

faulty printing caused by static charges in ink jet printing

process.

Use a bender nozzle.

●

Removal of static charges on electronic parts

Very low generation of electrical noise

・

No damage to a device caused by induction electric field by the

discharging needle.

・

Removal of static charges with pinpoint accuracy. (It is possible

to place the nozzle close to a device by using the tube.)

Note: Select a tube in accordance with the degree of tube flexibility.

●

Removal of static charges on

wrap film

Use blow type Ionizers with U-shaped

b a r n o z z l e s i n c o n f i n e d s p a c e t o

remove static charges on both sides of

the wrap film.

●

Removal of static charges on devices carried

by pallets

Use blow type Ionizers with straight bar nozzles to remove

static charges on a wide carrying pallet.

Use straight bar nozzles at

two places to remove static

charges.

●

Removal of static charges

in pipes (

φ

50 or less)

Inser ting the tube inside a pipe

enables removal of static charges.

●

Removal of static charges in bottles

(Removal of dust)

Use a spiral bar nozzle to remove static charges

inside a bottle.

Blows ionized air from the tip.

●

Removal of static charges on

glass substrate

Use 2-head type Ionizers with two

straight bar nozzles to remove static

charges on FPD glass.

Spirally blows ionized air from

the side surface of the bar.