8

Handling Instructions and Precautions

Mounting

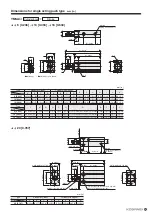

1.

Any mounting posture is available but the mounting surface

should be flat surface. Occurrence of twist or bending when in

installation could not only deteriorate the accuracy but also

cause air leakage or defective operations.

2.

Take caution that scratched or dented mounting surface of the

cylinder may deteriorate the flatness.

3.

When the impact is too large, be sure to install some support

bracket on the cylinder in addition to mounting screws.

4.

Ensure to keep enough strength for the cylinder and

mounting screws.

5.

When the screws may be loosened by the impact or vibration,

take measures against screw loosening.

6.

The sliding portion of the piston rod should not be scratched

or dented. Scratched or dented sliding portion could damage

seals and cause air leakage.

7.

Do not wipe out the grease applied on the piston rod and

linear guide. This may cause the product to defective

operation. If oil cannot be found, apply grease to them.

(Grease: Universal type Lithium based grease No. 2)

8.

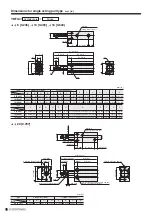

To tighten the cylinder, use the following tightening torque.

When using female threads of the main body for mounting,

tighten the screw under the tightening torque shown in ( ).

Mounting

Avoid the following usages.

9.

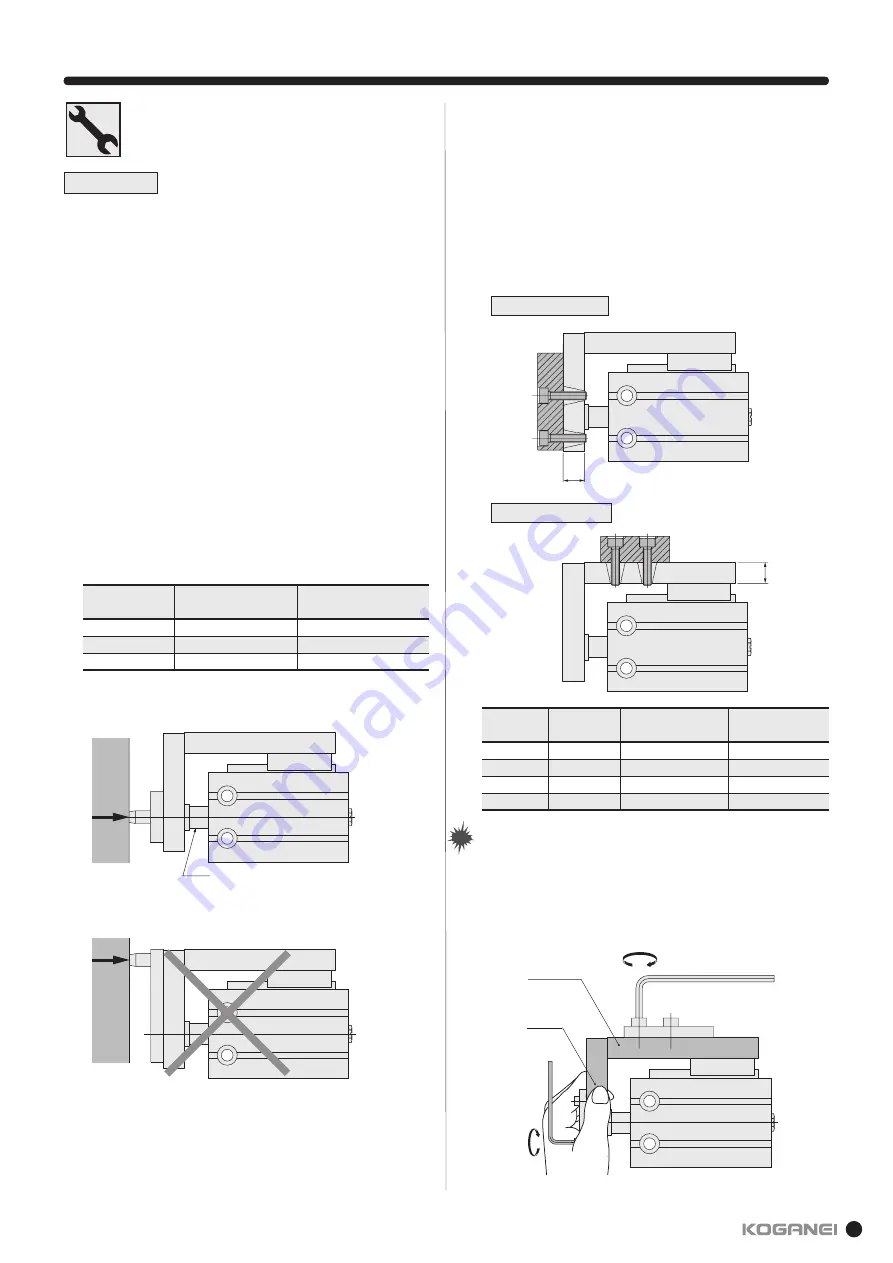

When thrust of a cylinder with guide directly apply to the plate,

apply the force to the rod axis center.

Cylinder bore

mm [in.]

6 [0.236] · 10 [0.394]

16 [0.630]

20 [0.787]

M3

×

0.5

M4

×

0.7

M5

×

0.8

1.08 [9.56] (0.59 [5.22])

2.45 [21.68] (1.37 [12.13])

5.10 [45.14] (2.84 [25.14])

Screw size

Tightening torque

N · m [in · lbf]

Rod

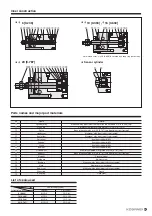

10. Mounting of workpiece

For the cylinder with guide, a workpiece can be mounted on

two surfaces.

To tighten screws for mounting a workpiece, tighten at a

torque within its limited range.

1.

As the plate table is supported by the linear guide, do not

apply strong impact or excessive moment to it when

mounting a workpiece.

2.

When securing a workpiece in a plate table with screws,

hold the table to tighten screws. Tightening with the body

held may apply excessive moment to the guide portion,

causing deteriorating the accuracy.

Cylinder bore

mm [in.]

0

6 [0.236]

10 [0.394]

16 [0.63]

20 [0.787]

M3

×

0.5

M3

×

0.5

M4

×

0.7

M5

×

0.8

0.59 [5.22]

0.59 [5.22]

1.37 [12.13]

2.84 [25.14]

5 [0.197]

6 [0.236]

8 [0.315]

10 [0.394]

Screw size

Maximum tightening torque

N · m [in · lbf]

H

mm [in.]

Front surface mounting

H

Upper surface mounting

H

Table

Plate

Note

Note

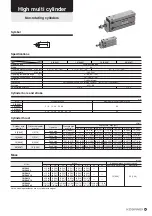

Summary of Contents for YMDA Series

Page 34: ...33 MEMO ...