TP-6073 4/06

73

Section 10 Wiring Diagrams

4

3

2

1

Stator Leads

L0

GRD.

L2

L1

L0 (Neutral)

Line

Side

Factory

Two-Pole

Circuit

Breaker

Ground

Load

Side

100-120/200-240 Volt,

3 Wire

60 Hz

50 Hz

L0-L1

100-120 Volt

100-120 Volt

L0-L2

100-120 Volt

100-120 Volt

L0-L2

200-240 Volt

200-240 Volt

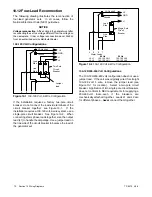

Figure 10-3

100-120/200-240 Volt

3-Wire Configuration

200-240 Volt Configurations

The 200-240 volt configuration does not use a jumper

lead. If the unit was originally wired for straight 100-120

volt, 3 wire, remove the jumper lead (see Figure 10-1 for

location).

4

3

2

1

Stator Leads

L0

GRD.

L1

L0 (Neutral)

Line

Side

Single-Pole

Circuit

Breaker

Ground

Load

Side

200-220-240 Volt

2 Wire

Tape to insulate

from ground

60 Hz

L0-L1

not used

200-220-240 Volt

50 Hz

Figure 10-4

200-220-240 Volt 2-Wire Configuration

10.13Twelve-Lead Reconnection

The reconnection procedure that follows details voltage

reconnections only.

If the generator set requires

frequency changes, adjust the governor and voltage

regulator. See the generator set service manual for

information regarding frequency adjustment.

In all cases, follow National Electrical Code (NEC)

guidelines.

Reconnect the stator leads of the generator set to

change output phase or voltage. Refer to the following

procedure and connection schematics. Follow all safety

precautions at the front of this manual and in the text

during reconnection procedure.

NOTICE

Voltage reconnection.

Affix a notice to the generator set after

reconnecting the set to a voltage different from the voltage on

the nameplate. Order voltage reconnection decal 246242

from an authorized service distributor/dealer.

Twelve-Lead Reconnection Procedure

1. Move generator set start/stop switch to the STOP

position.

2. Disconnect engine starting battery, negative (--)

lead first. Disconnect power to battery charger, if

equipped.

3. Use Figure 10-5 to determine generator set

voltage configuration. Note original voltage and

reconnect as needed.

Summary of Contents for 10EOR

Page 10: ...10 Safety Precautions and Instructions TP 6073 4 06 Notes...

Page 12: ...TP 6073 4 06 12 Service Assistance Notes...

Page 22: ...TP 6073 4 06 22 Section 3 Intake and Exhaust System Notes...

Page 26: ...TP 6073 4 06 26 Section 4 Fuel System Notes...

Page 30: ...TP 6073 4 06 30 Section 5 Cooling System Notes...

Page 38: ...TP 6073 4 06 38 Section 6 Controller Troubleshooting Notes...

Page 54: ...TP 6073 4 06 54 Section 8 Component Troubleshooting Notes...

Page 60: ...TP 6073 4 06 60 Section 9 Generator Disassembly Reassembly Notes...

Page 82: ...TP 6073 4 06 82...

Page 83: ...TP 6073 4 06 83...