TP-6196 10/09

126 Appendix

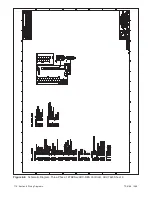

Appendix C General Torque Specifications

American Standard Fasteners Torque Specifications

Size

Torque

Measurement

Assembled into Cast Iron or Steel

Assembled into

Aluminum

Grade 2 or 5

Grade 2

Grade 5

Grade 8

8-32

Nm (in. lb.)

1.8

(16)

2.3

(20)

—

See Note 3

10-24

Nm (in. lb.)

2.9

(26)

3.6

(32)

—

10-32

Nm (in. lb.)

2.9

(26)

3.6

(32)

—

1/4-20

Nm (in. lb.)

6.8

(60)

10.8

(96)

14.9

(132)

1/4-28

Nm (in. lb.)

8.1

(72)

12.2

(108)

16.3

(144)

5/16-18

Nm (in. lb.)

13.6

(120)

21.7

(192)

29.8

(264)

5/16-24

Nm (in. lb.)

14.9

(132)

23.1

(204)

32.5

(288)

3/8-16

Nm (ft. lb.)

24.0

(18)

38.0

(28)

53.0

(39)

3/8-24

Nm (ft. lb.)

27.0

(20)

42.0

(31)

60.0

(44)

7/16-14

Nm (ft. lb.)

39.0

(29)

60.0

(44)

85.0

(63)

7/16-20

Nm (ft. lb.)

43.0

(32)

68.0

(50)

95.0

(70)

1/2-13

Nm (ft. lb.)

60.0

(44)

92.0

(68)

130.0

(96)

1/2-20

Nm (ft. lb.)

66.0

(49)

103.0

(76)

146.0

(108)

9/16-12

Nm (ft. lb.)

81.0

(60)

133.0

(98)

187.0

(138)

9/16-18

Nm (ft. lb.)

91.0

(67)

148.0

(109)

209.0

(154)

5/8-11

Nm (ft. lb.)

113.0

(83)

183.0

(135)

259.0

(191)

5/8-18

Nm (ft. lb.)

128.0

(94)

208.0

(153)

293.0

(216)

3/4-10

Nm (ft. lb.)

199.0

(147)

325.0

(240)

458.0

(338)

3/4-16

Nm (ft. lb.)

222.0

(164)

363.0

(268)

513.0

(378)

1-8

Nm (ft. lb.)

259.0

(191)

721.0

(532)

1109.0

(818)

1-12

Nm (ft. lb.)

283.0

(209)

789.0

(582)

1214.0

(895)

Metric Fasteners Torque Specifications, Measured in Nm (ft. lb.)

Size (mm)

Assembled into Cast Iron or Steel

Assembled into

Aluminum

Grade 5.8 or 8.8

Grade 5.8

Grade 8.8

Grade 10.9

M6

x 1.00

6.2

(4.6)

9.5

(7)

13.6

(10)

See Note 3

M8

x 1.25

15.0

(11)

23.0

(17)

33.0

(24)

M8

x 1.00

16.0

(11)

24.0

(18)

34.0

(25)

M10 x 1.50

30.0

(22)

45.0

(34)

65.0

(48)

M10 x 1.25

31.0

(23)

47.0

(35)

68.0

(50)

M12 x 1.75

53.0

(39)

80.0

(59)

115.0

(85)

M12 x 1.50

56.0

(41)

85.0

(63)

122.0

(90)

M14 x 2.00

83.0

(61)

126.0

(93)

180.0

(133)

M14 x 1.50

87.0

(64)

133.0

(98)

190.0

(140)

M16 x 2.00

127.0

(94)

194.0

(143)

278.0

(205)

M16 x 1.50

132.0

(97)

201.0

(148)

287.0

(212)

M18 x 2.50

179.0

(132)

273.0

(201)

390.0

(288)

M18 x 1.50

189.0

(140)

289.0

(213)

413.0

(305)

Notes:

1.

The torque values above are general guidelines. Always use the torque values specified in the service manuals and/or assembly

drawings when they differ from the above torque values.

2.

The torque values above are based on new plated threads. Increase torque values by 15% if non-plated threads are used.

3.

Hardware threaded into aluminum must have either two diameters of thread engagement or a 30% or more reduction in the torque to

prevent stripped threads.

4.

Torque values are calculated as equivalent stress loading on American hardware with an approximate preload of 90% of the yield strength

and a friction coefficient of 0.125.

Summary of Contents for 12RES

Page 2: ......

Page 6: ...TP 6196 10 09 6 Notes ...

Page 34: ...TP 6196 10 09 34 Section 3 Troubleshooting Notes ...

Page 52: ...TP 6196 10 09 52 Section 4 ADC 2100 and DC 2200 Controllers Notes ...

Page 72: ...TP 6196 10 09 72 Section 5 ADC RES and DC RET Controller Notes ...

Page 100: ...TP 6196 10 09 100 Section 6 Component Testing and Adjustment Notes ...

Page 131: ......