TT-1303

7/02

7

3.6

GM17071-KP3 and GM17071-KP3S kits only

(450--2000 kW).

Swing the access door closed

and install the screws.

3.7

Replace the junction box panel and hardware.

4.

Select a mounting location for the remote

annunciator panel.

4.1

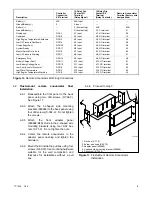

Select a visible location for mounting the remote

annunciator panel. Install the remote annunciator

panel, either surface- or flush-mounted, in a

location easily observable by operating personnel

at their work stations. See Figure 8 for remote

annunciator dimensions and mounting hole

dimensions.

4.2

Surface-mount

remote

annunciator

initial

installation.

4.2.1

Prepare the mounting site by drilling pilot

holes for anchors, if used.

Note:

Mount the remote annunciator kit to

a standard 10 cm (4 in.) square

electrical box installed in the wall.

4.2.2

Create an opening in the wall for the

electrical wiring from the 14-relay dry

contact assembly, P and N battery

connections, and transfer switch.

4.2.3

Disassemble the remote annunciator box.

Remove six drill screws to disassemble

the side panels and separate the front and

back remote annunciator panels. Retain

the side panels (287798) and the drill

screws (X-794-2) for reassembly.

4.2.4

Mount the remote annunciator back panel

to the wall or to the electrical box in the

wall. See Figure 8 for the mounting hole

dimensions.

Protect

the

remote

annunciator from dust and debris when

drilling the holes.

Note:

Use mounting hardware suitable for the

wall composition and thickness.

4.2.5

Proceed to step 5, Wire the remote

annunciator.

PREALARM

HIGH ENGINE

TEMPERATURE

PREALARM

LOW OIL

PRESSURE

LOW WATER

TEMPERATURE

LOW FUEL

HIGH ENGINE

TEMPERATURE

LOW OIL

PRESSURE

EMERGENCY

STOP

OVERSPEED

BATTERY

CHARGER FAULT

LOW BATTERY

VOLTAGE

AUXILARY

FAULT

OVERCRANK

LINE

POWER

GENERATOR

POWER

SYSTEM

READY

GENERATOR

SWITCH

NOT IN AUTO

NORMAL

SILENCE

LAMP

TEST

ALARM

42B

35

63

41 40 39 48 38 36 12 26 62 61 58 59 60 80 N

To Annunciator

Contact Box

To Transfer Panel

(Remaining Leads)

(58, 59)

PREALARM

HIGH ENGINE

TEMPERATURE

PREALARM

LOW OIL

PRESSURE

LOW WATER

TEMPERATURE

LOW FUEL

HIGH ENGINE

TEMPERATURE

LOW OIL

PRESSURE

EMERGENCY

STOP

OVERSPEED

BATTERY

CHARGER FAULT

LOW BATTERY

VOLTAGE

AUXILARY

FAULT

OVERCRANK

LINE

POWER

GENERATOR

POWER

SYSTEM

READY

GENERATOR

SWITCH

NOT IN AUTO

NORMAL

SILENCE

LAMP

TEST

ALARM

2.59 [66]

8.32 [211]

13.50 [343]

1.03

[26]

7.44

[189]

9.50

[241]

0.19

[5]

4.62

[1

17]

5.00

[127]

8.69 [221]

2.38 [60]

3.38 [86]

2.66 [68]

3.38

[86]

0.81

[21]

0.219 [6]

4 Holes

4.35 [110]

3.38

[86]

2.11 [54]

4 HOLES

Surface Mount

Flush Mount

ADV-5957-

0.219 [4]

4.62

[1

17]

Note:

This view is shown as seen from the front, with the front panel removed.

Note:

Dimensions in [ ] are millimeter equivalents.

Figure 8

Component Dimensions