10. Check Installation and Operation

Plug the pump into the outlet.

Verify that the electrical supply to the outlet is on.

Verify that the pump banding straps have been cut, and that the pump is resting directly on the

footbath sled.

Turn on the water supplies and check all connections for leaks.

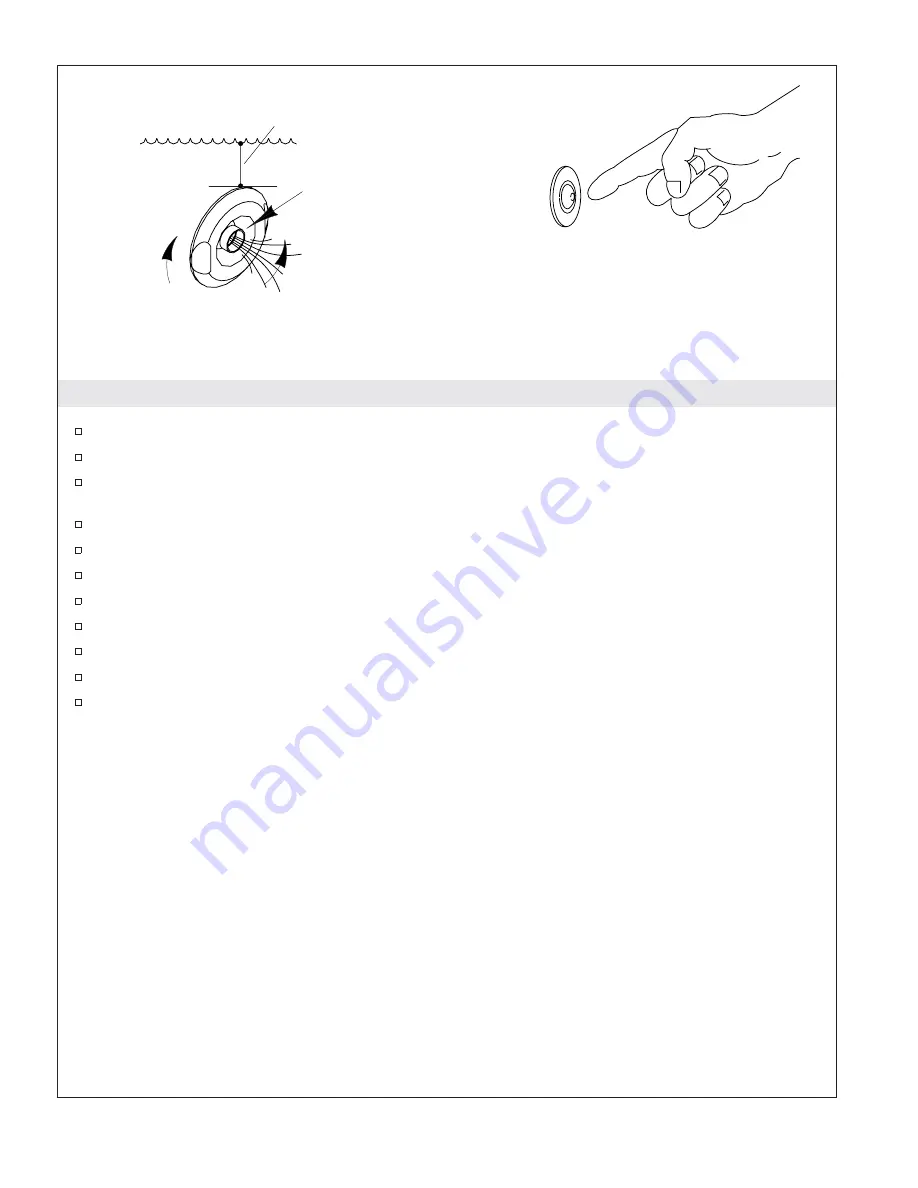

Position the jet nozzles to point toward the bottom of the footbath.

Verify the air switch tubing is securely attached to the pump, and is not kinked or damaged.

Fill the footbath to a level at least 2” (5.1 cm) above the highest jet.

Press the air switch to turn on the footbath.

Allow the footbath to run for approximately 5 minutes and check all piping connections for leaks.

Rotate the jet trim rings to increase (counterclockwise) or decrease (clockwise) the flow.

Press the air switch again to turn off the footbath.

Fill with water at least 2" (5.1 cm)

above the highest jet.

Turn the jet trim ring

clockwise to

decrease the flow.

Position the jet

nozzles to direct

the water flow as

desired.

Turn the jet trim ring counterclockwise

to increase the flow.

Press the air switch to turn the

whirlpool on or off.

1063564-2-D

12

Kohler Co.

Summary of Contents for K-1006

Page 1: ...Installation Guide Pedicure Spa K 163 K 1006 K 1011 K 1012 1063564 2 D...

Page 17: ...1063564 2 D...

Page 18: ...1063564 2 D...

Page 19: ...1063564 2 D...