- 31 -

- 31 -

51

50

49

48

13

The instructions refer to engines updated at the time

of publication. Check the technical circulars for any

modifications.

Thoroughly clean the parts before remounting them.

Lubricate the moving parts to prevent seizures when the

engine is first started.

Replace the seals whenever the parts are remounted.

Use torque wrenches to tighten to the correct values.

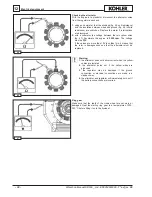

Preparing the engine block

Remove all traces of sealant or impurities from the bearing

surfaces with a copper plate or lapping stone, then proceed in

the following way:

1.

Fit on the oil drain plugs without tightening them too much

(max. 2 Kgm) to prevent damage to the threads.

2.

Mount the main bearing as indicated at page 18.

3.

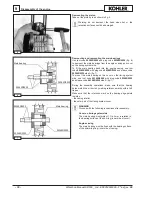

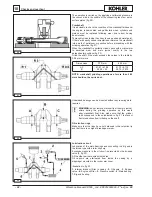

Fit the benzing ring on to the pin of the regulator levers (fig.

48 -

A

); apply Loctite 648 to the zone where the pin touches

the engine casing.

Insert the stop lever (fig. 48 -

B

), the accelerator lever (fig.

49 -

C

) and complete the assembly operations in compliance

with the sequencies indicated in figures 48 and 49.

4.

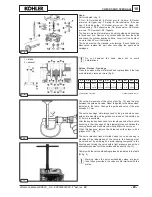

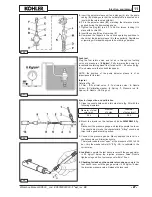

Comply with the sequence indicated in fig. 50 for the

"motorstop" version.

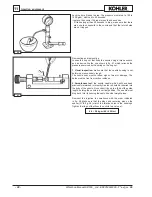

Injection pump tappets

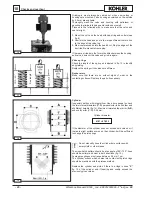

Insert the tappet into the injection pump housing in the engine

casing.

Fit the screw into the guide as shown in fig. 51.

ENGINE ASSEMBLY

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00