8

- 24 -

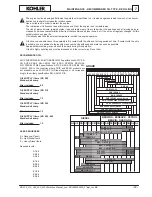

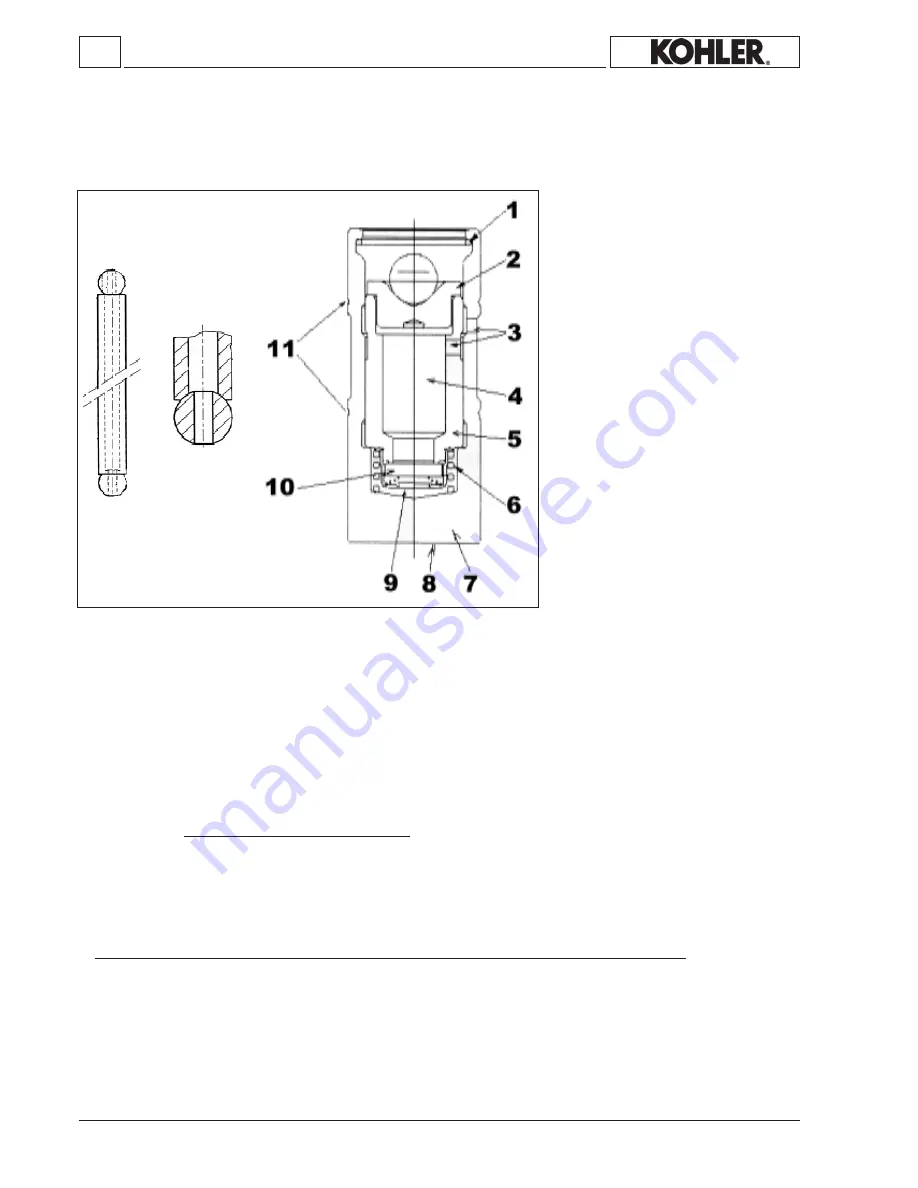

DISASSEMBLY/REASSEMBLY

Caption

1

- Lock ring

2

- Upper collar

3

- Oil inlet holes

4

- Low-pressure chamber

5

- Piston

6

- Play-recovery spring

7

- Case

8

- Area to be lubricated

9

- High-pressure chamber

10

- Check valve

11

- Identification marks

Fill the low-pressure chamber through the oil inlet holes.

If clearance occurs while running, as the tappet returns to the base of the camshaft, the play-recovery spring stretches out,

keeping all timing system parts close together.

While the play-recovery spring is stretching, the check valve lets oil into the high-pressure chamber from the low-pressure

chamber, to recover the increase in volume in the high-pressure chamber, caused by the stretching spring. In this way, since oil

is practically uncontrollable, when the valve is next opened, play will be completely recovered.

During each cycle a small amount of oil is drawn from the high-pressure chamber into the piston coupling wall with the case and

then, passing through the internal inlet hole, flows into the low-pressure chamber.

The tappet is shortened by less than 0.1mm each cycle. This allows the tappet to make up the reduction in play while the engine

is running.

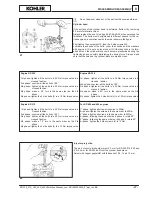

It is not necessary for the oil to reach the tappet on the downward stroke: light pressure is enough to ensure that air bubbles do

not form.

The tappet may be supplied with the high-pressure chamber full or empty. The low-pressure chamber is always empty.

The tappet should always be handled in an upright position to prevent the high-pressure chamber from emptying.

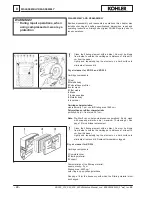

The surface that comes into contact with the cam should be lubricated generously during assembly using AS COMPUND 40

type MOLYSLIP (see figure). This operation is important to ensure correct lubrication right from the start.

The distribution system is assembled as follows:

a) Make sure that the piston is between the Bottom Dead Centre and the halfway point

b) Insert the rods into position on the tappets

c) Mount the rocker arm and the joint block, then tighten the fixing nut to the specified torque

d) DO NOT START THE ENGINE FOR AT LEAST 4 HOURS AFTER TIGHTENING THE ROCKER ARMS because the valve-

piston contact may be put at risk.

The tappet is unloaded when it is possible to shift the internal part by 3.5÷4 mm using a force of 30 Nm.

If the tappets are loaded (for example if they have been left in a horizontal position) the engine will be noisy during the first few

minutes after switching on, until the air has been completely drained out of the inside of the tappets themselves.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_

1° ed

_ rev.

00

Hydraulic tappets KD 400-440

Distribution uses hydraulic tappets for automatic adjustment of valve clearance.

The figure shows the tappet used in KD 400 engines.