49

50

48

8

0

5

4

,

0

÷

1

5

3

,

0

9

,

0

0

0

5

,

0

÷

5

6

3

,

0

1

0

5

5

,

0

÷

0

5

4

,

0

1

0

0

6

,

0

÷

0

0

5

,

0

1

,

1

0

5

6

,

0

÷

0

5

5

,

0

1

,

1

0

0

7

,

0

÷

0

0

6

,

0

2

,

1

0

5

7

,

0

÷

0

5

6

,

0

2

,

1

0

5

4

,

0

÷

5

6

3

,

0

9

,

0

0

0

5

,

0

÷

0

1

4

,

0

1

0

5

5

,

0

÷

0

5

4

,

0

1

0

0

6

,

0

÷

0

1

5

,

0

1

,

1

0

5

6

,

0

÷

0

5

5

,

0

1

,

1

0

0

7

,

0

÷

0

1

6

,

0

2

,

1

0

5

7

,

0

÷

0

5

6

,

0

2

,

1

0

0

4

,

0

÷

5

6

3

,

0

9

,

0

0

0

5

,

0

÷

0

1

4

,

0

1

0

0

5

,

0

÷

0

0

4

,

0

1

0

0

6

,

0

÷

0

1

5

,

0

1

,

1

0

0

6

,

0

÷

0

0

5

,

0

1

,

1

0

0

7

,

0

÷

0

1

6

,

0

2

,

1

0

0

7

,

0

÷

0

0

6

,

0

2

,

1

- 35 -

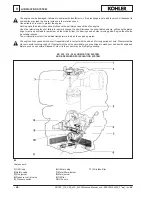

DISASSEMBLY/REASSEMBLY

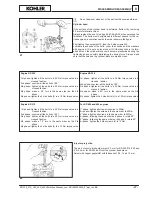

Piston protrusion check

To calculate the right thickness for the gasket, the protrusion between

the piston and the cylinder head surface must be measured.

Use a dial indicator with base plate. Reset to zero while resting on a

surface plate, then position against the cylinder head base plane as

shown in the diagram, so that the dial indicator rod rests against the

piston. Now take the reading.

Repeat the operation in the other three points (going crosswise) and

take the readings.

Calculate the average of these four readings to get the precise

measurement of the protrusion between the piston and the cylinder

head base plane.

Choose the appropriate gasket according to the following table.

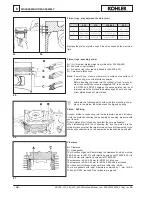

Only remove the head gasket from its protective wrapping just

before assembly.

See page 26 when tightening the cylinder head

Having chosen the required thickness, mount the gasket as shown in

the figure (see letter

A

).

Find the number of notches in zone

B

to find the thickness of the ga-

sket when the cylinder head is mounted.

The gasket thickness given in the table is the one obtained with the

gasket mounted and the head torqued.

Head gasket (mm)

0

1 notch

2 notches

3 notches

0

1 notch

2 notches

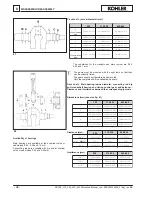

Piston

protusion

Gasket

Thickness

Number

of notches

Number

of notches

Gasket

Thickness

Piston

protusion

Piston

protusion

Gasket

Thickness

Number

of notches

Number

of notches

Gasket

Thickness

Piston

protusion

0

1 notch

2 notches

3 notches

0

1 notch

2 notches

0

1 notch

2 notches

3 notches

0

1 notch

2 notches

Number

of notches

Gasket

Thickness

Piston

protusion

Number

of notches

Gasket

Thickness

Piston

protusion

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_

1° ed

_ rev.

00

For KD 315 with injection pump P.no 6590.259

For KD 225

For KD 350

For KD 400

For KD 315 with injection pump P.no 6590.281

For KD 440