145

146

143

144

12

- 68 -

SETTINGS / ADJUSTMENTS

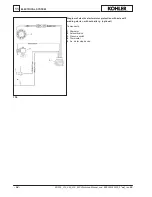

No-load idling adjustment (standard)

After having filled the engine with oil and fuel, start it and allow it to

warm up for 10 minutes.

Using adjuster screw

1

, regulate the idling rate at 1000-1250 rpm.

Tighten the check nut.

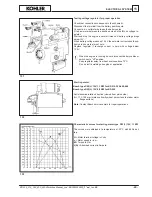

No-load top rate adjustment (standard)

After having adjusted the idling rate, use screw

2

and regulate the top

rate at 3800 rpm (for engines set at 3600 rpm on load).

Tighten the check nut.

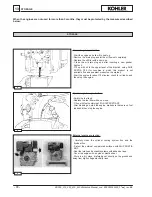

Injection pump flow rate adjustment

This regulation must be carried out by means of a water brake, other-

wise the adjustment will be approximate. proceed in the following way.

Loosen flow rate limiter

C

by 5 turns.

Accelerate the engine to no-load top rate, i.e. to 3800 rpm.

Re-tighten limiter

C

until the engine tends to decelerate.

Loosen limiter

C

by one and a half turns.

Tighten the check nut.

Note:

Tighten

C

if the engine produces an excessive amount of exhaust

in the maximum load condition; loosen

C

if no smoke is exhausted

and if the engine is unable to develop its maximum power.

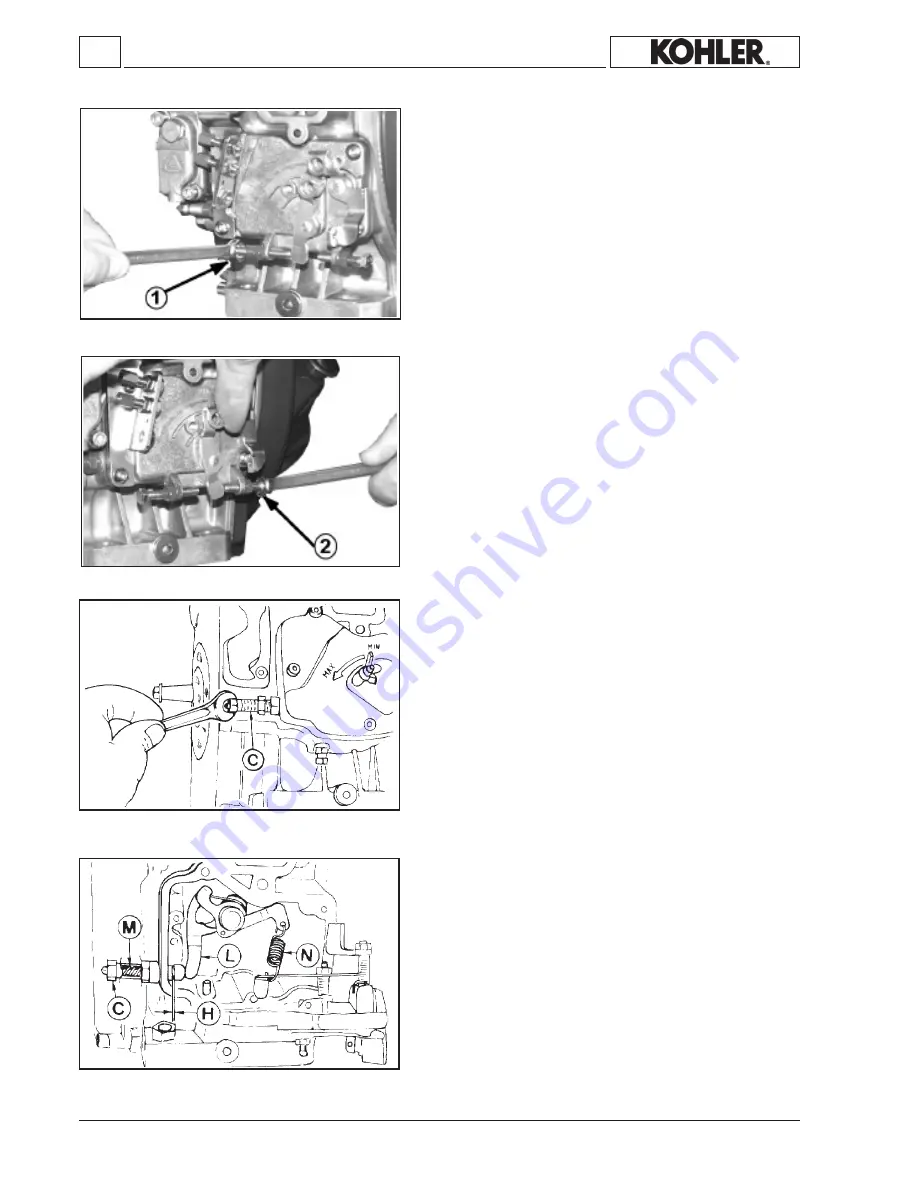

Injection pump delivery limiting and torque adapter (standard)

Delivery limiting device

C

has the function of limiting the injection pump

max. delivery.

The same device also acts as torque adapter. The speed governor

spring acts on lever

L

with standing the resistance opposed by spring

M

inside the cylinder.

The stroke

H

allowed by the torque device to lever

L

is 0.20 / 0.25 mm.

As a result of this pump delivery increases and torque reaces its peak

value.

Note:

In generator sets and power welders, the torque setting device

acts as a delivery limiter only.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_

1° ed

_ rev.

00

for KD

225-315-350-400-440

ADJUSTMENTS - KD 225-400-440