5

_14

.1

25

5.6

A

5.7

E

F

F

B1

D

B2

C

A

A

EN

5.6 Check of the radiator heat-exchanger surface

NOTE:

Component not necessarily supplied by

KOHLER.

Important

• Wear safety goggles when using compressed air.

• The radiator heat-exchange surface must be cleaned on

both sides.

1.

Check the radiator heat-exchange surface A.

2.

Clean the surface with a brush soaked in special detergent

if it is clogged.

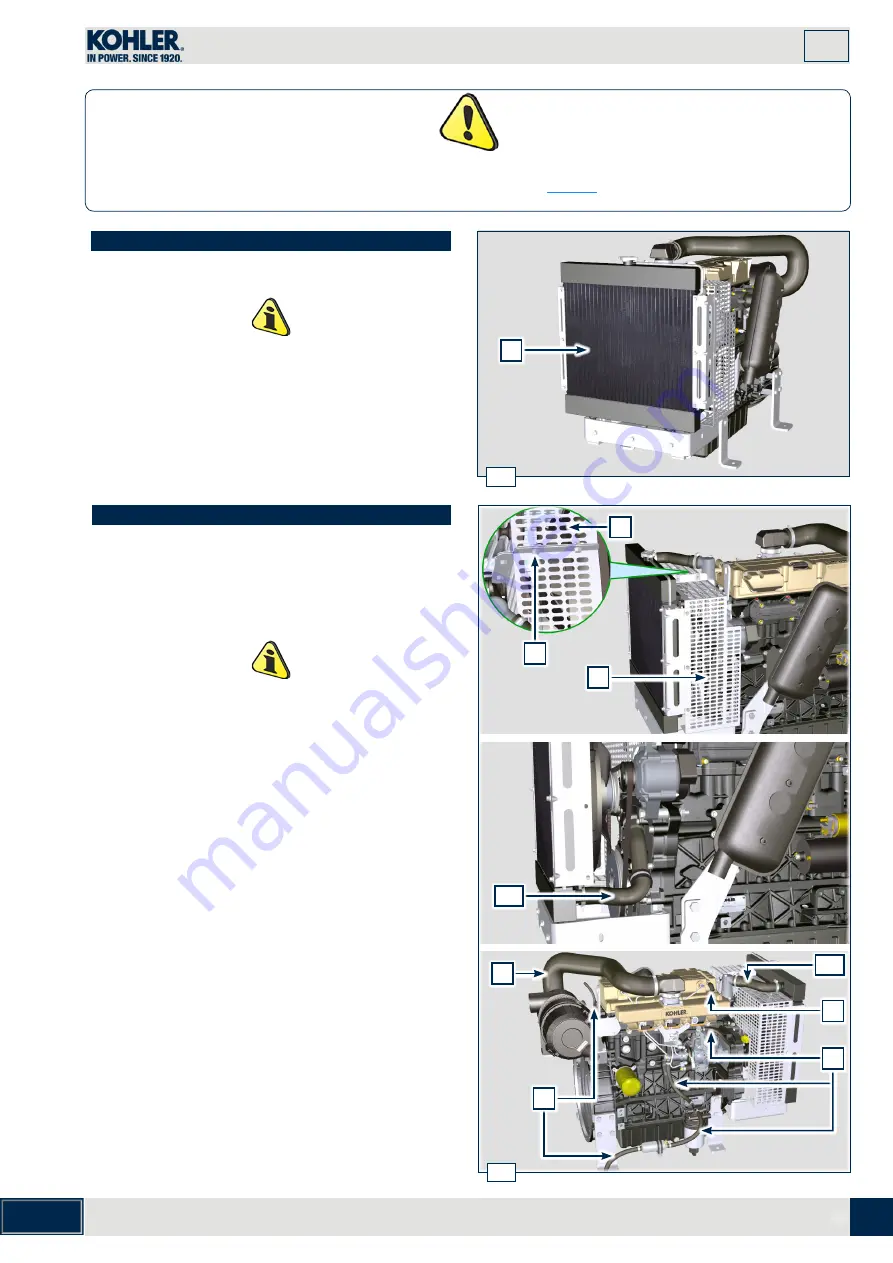

5.7 Rubber hoses check

The check is carried out by exerting a slight deflection or

bending along the pipe and near the hose clamps.

Components must be replaced if they have clear signs of

cracks, tears, cuts, leaks and do not retain a certain degree

of elasticity.

Important

• If hoses are damaged contact an authorized KOHLER

workshop.

1.

Loosen the four capscrews E. Remove guard F.

2.

Check that the:

- Fuel system hoses

A

are intact.

-

Hoses for the cooling circuit B1 and B2.

To access the control of the cooling hoses B1 unscrew the

four screws E and remove the safe guard F.

- Vent system pipes

C

.

- Air system ducts

D

.

When the control is finished the safe guard F mount and

tighten the four screws E.

Danger

•

For safety precautions see

ED0053029510

Index