10

Warning! Turn off the electrical and water supplies before proceeding with the

installation of the Mira Escape. The electricity must be turned off at the mains

and the appropriate circuit fuse removed, if applicable.

Note! An installation template is supplied to help you install the Mira Escape.

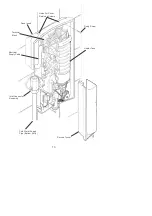

Remove the three cover retaining

screws, the cover and the service

tunnel.

Cover

Cover Retaining

Screw

Service Tunnel

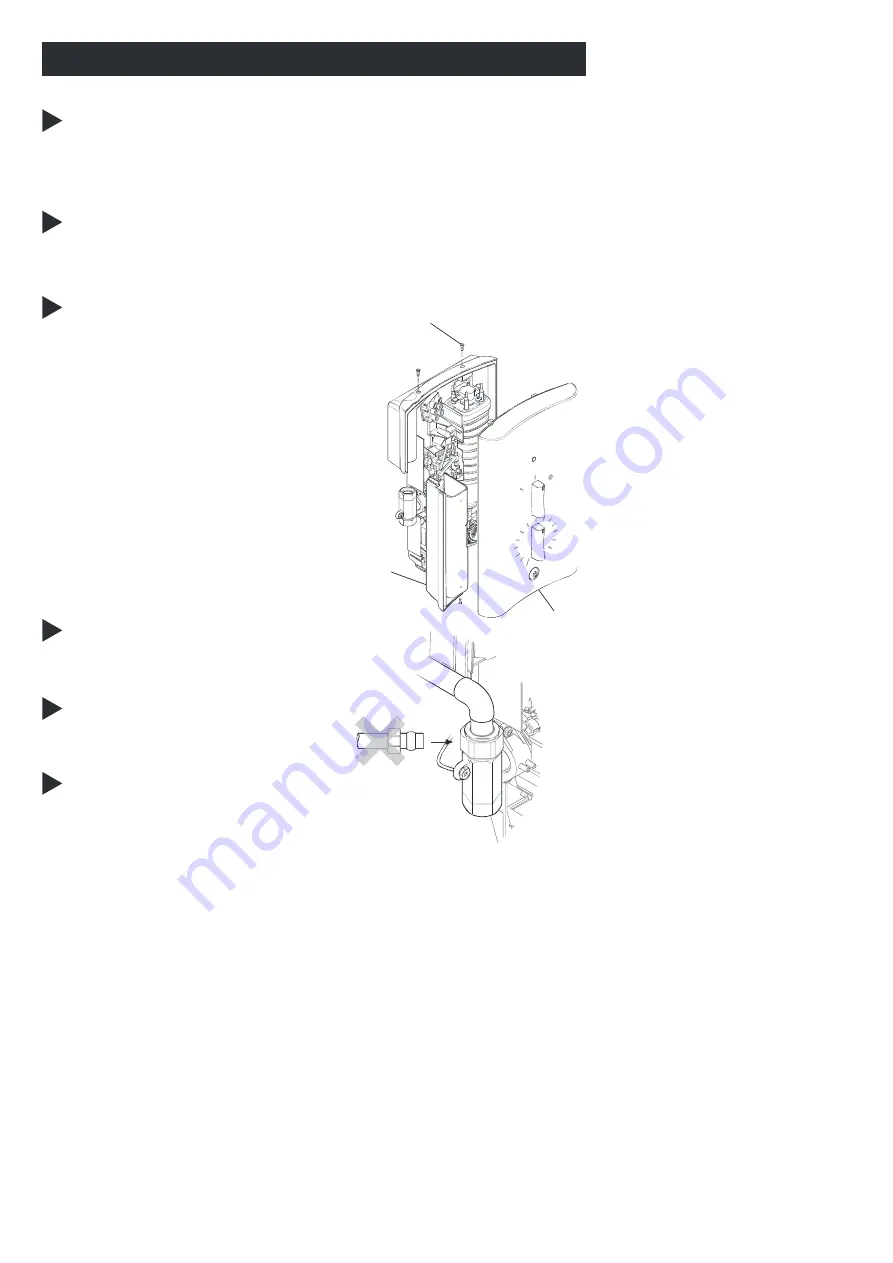

Determine the direction of the inlet

water supply: top (falling), bottom

(rising), or back inlet .

Note! Make sure that the back inlet

does not go directly back into the wall.

Use a soldered elbow.

Swivel the inlet connector assembly

to suit. Remove the inlet blanking cap.

Avoid trapping the green earth bonding

wire.

INSTALLATION

Installation of Mira Escape

Wall ¿xings are not supplied. For solid wall structures a red rawl plug and a

no. 8 x 1½” countersunk brass or stainless steel screw should be used. For

other wall structures such as panels alternative ¿xings may be required. A

minimum of 3 ¿xing screws should be used.