10

113019-

CA

(1093)

Kohler Co., Kohler WI

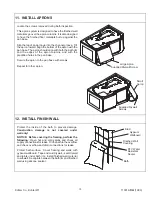

D. SECURE BATH

Secure the nailing flange to the stud pocket header with

screws supplied with unit.

After the unit is secured to the header to prevent

spreading or squeezing of bath walls, remove the

shipping spreader bar. Test operation of door to assure

there is no binding from installation.

Supplied

Pan Head

Screws

Spacer

Bar

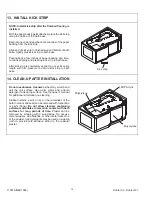

8. COMPONENT LOCATION

Familiarize yourself with the location of all major

components before proceeding to field wiring (by a

licensed electrician), suction elbow adjustment, trim kit

installation, and testing and troubleshooting.

This unit uses a compressor assembly to inflate a seal

in the door. The door has a backup gasket on the outside

for added safety.

A bolt-type latch secures the door. It is released by the

button on top of the door. After the button is depressed,

slight pressure inward should open the door.

Button

Door

Seat

Inflatable

Seal

Back

Up

Gasket

Air Line

Air Compressor

Control Box

Air Compressor