12

113019-

CA

(1093)

Kohler Co., Kohler WI

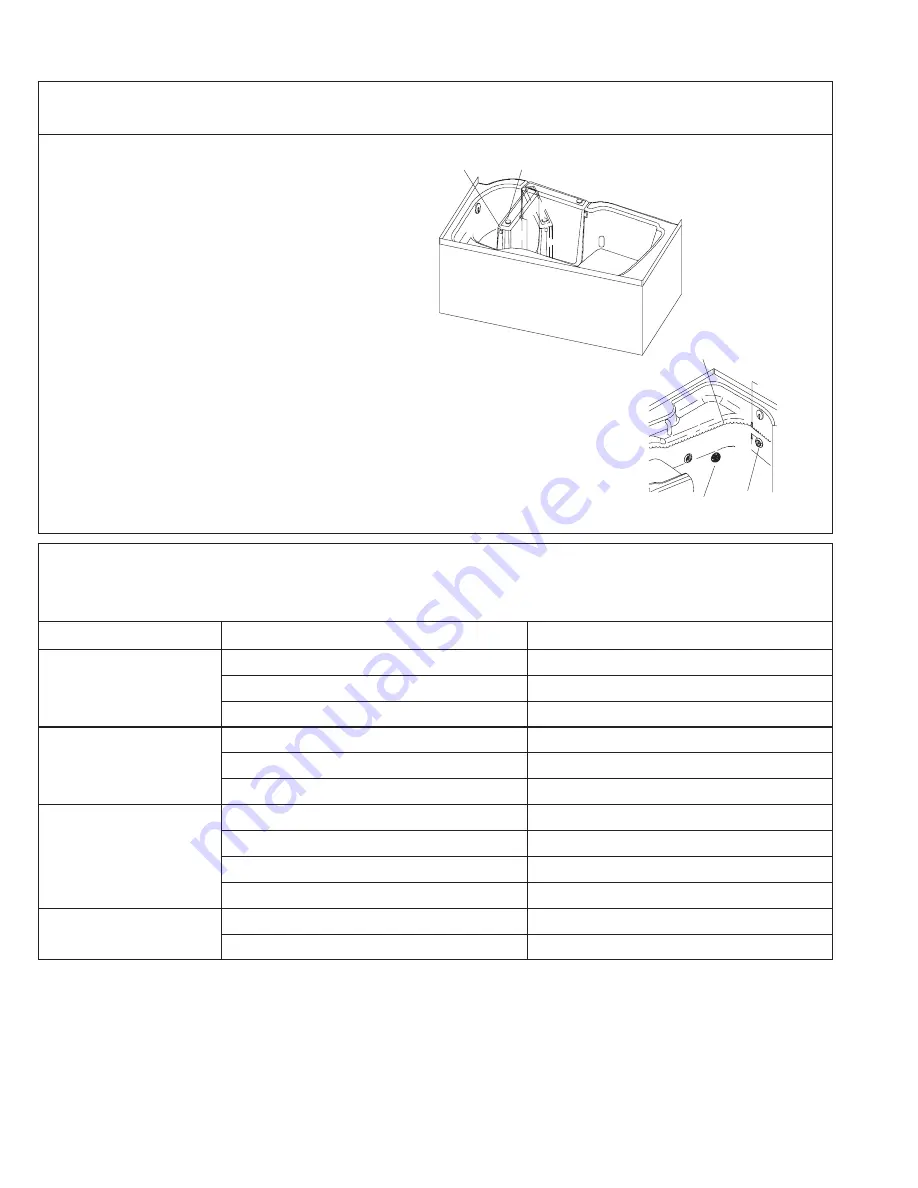

10. TEST DOOR SYSTEM

A. OPERATING SEQUENCE

Tightly close the door. When swinging the door shut, a

clicking sound assures the door is closed and secure.

Check that door latch engages the latch receptor.

Close drain and begin filling bath.

The door seal will inflate automatically after the two

water level sensors inside the bath near the bottom of

the door are covered with water.

Monitor outside of door for any signs of leaks and

continue to fill bath to a water level at least 2” above the

top of the highest jet.

Open drain and allow bath to empty.

The door seal will automatically deflate when water level

lowers below the water level sensors.

Press in the button on top of the door and open door

inward.

Latch

Button

Suction

Bath Jet

Water

Line

2” Min.

B. TROUBLESHOOT DOOR SYSTEM

This troubleshooting guide is for general aid only. A Kohler Authorized Service Representative or a qualified electrician

should correct all electrical problems. For warranty service, contact your dealer or wholesale distributor.

SYMPTOMS

PROBABLE CAUSES

RECOMMENDED ACTION

1. Door won’t close.

A. Seal is out of track.

A. Re-insert seal.

B. Seal remains inflated.

B. Contact dealer/installer.

C. Improper installation.

C. Contact dealer/installer.

2. Door won’t open.

A. Tub is not empty.

A. Wait for tub to empty.

B. No power to unit.

B. Reset breaker.

C. Compressor controller.

C. Contact dealer/installer.

3. Door leaks water.

A. No power to unit.

A. Reset breaker.

B. Incorrect field wiring.

B. Contact dealer/installer.

C. Seal is leaking.

C. Contact dealer/installer.

D. Compressor controller.

D. Contact dealer/installer.

4. Compressor runs

periodically

A. Seal is leaking air.

A. Contact dealer/installer.

periodically.

B. Faulty pressure switch.

B. Contact dealer/installer.