7

113019-

CA

(1093)

Kohler Co., Kohler WI

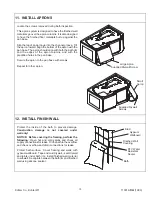

C. REMOVE APRONS AND INSPECT UNIT

Carefully uncrate and inspect the bath for damage. Do

not remove spacer bar until unit is secured to stud

pocket.

Loosen and remove the screws at the base of the two

aprons. These screws secure the aprons to the pan

base. Save these screws.

Pull bottom of apron away from bath unit and then pull

top down and out from flange in bath rim.

Continue inspection of bath for damage.

Reinstall aprons if unit is not immediately installed.

Return bath to carton during construction to prevent

damage.

Large

Apron

Small

Apron

Supplied Drywall Screws

Spacer

Bar

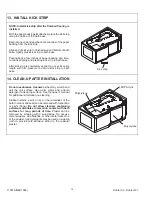

D. STUD POCKET PREPARATION

Refer to Roughing-In section beginning on page 4.

Measure the exact outside dimension of the bath from

the two front edges of the nailing flange. This should be

close to 60”. Size the stud pocket accordingly.

NOTE: The stud pocket must fit the width of the unit

exactly. The bath is shipped with a spacer bar to pre-

vent spreading or squeezing of the door opening.

This would affect the proper function of the inflat-

able seal.

Construct a recess designed for your particular

installation. Install stud pocket headers.

Construct the required access panel according to

Roughing-In section beginning on page 4.

Design of bath will allow for up to 1/2” of finish floor

material if the bath is installed to the subfloor. For thicker

flooring, raise bath with plywood underlayment to

compensate. This is necessary to allow clearance for

apron removal.

Stud Pocket

NOTE: Refer to instructions

32” Min.

NOTE: Nailing

flange holes in

unit are 24-3/4”

from base of

unit

Header Nailing

Flange

NOTE: Allow adequate clearance for plumbing.

Centerline of drain is 23-1/8” from back of unit.

E. PLUMBING PREPARATION

Position plumbing according to roughing-in dimensions.

Cap supplies and check for leaks.