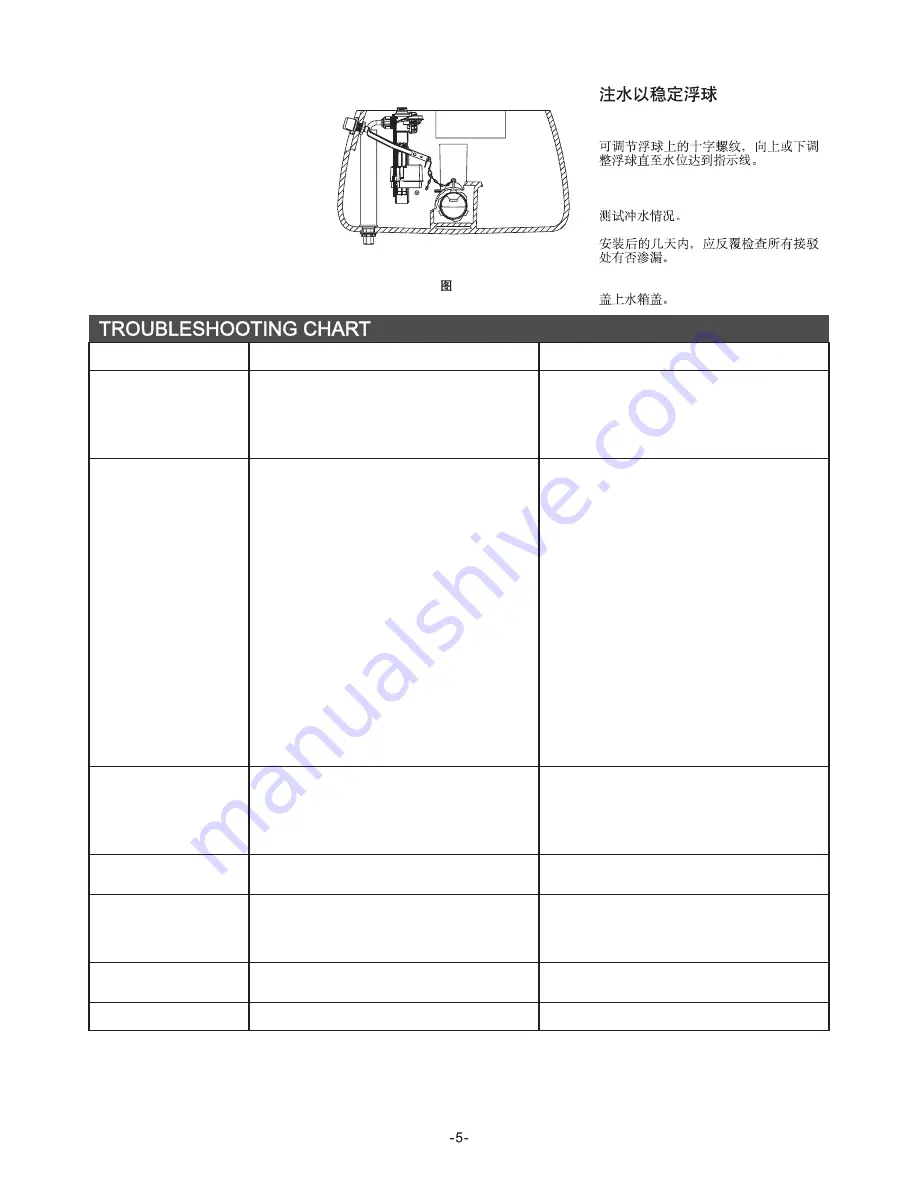

FILL FLOAT WITH

BALLAST

Adjust the float by the cross-shaped

thread and sliding it up or down on the

float rod until the water level is at the

marked water line.

Test flush the toilet.

Check all connections for leakage for

several days.

Set the tank cover in place on the tank.

Fig.#9

9

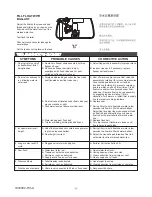

SYMPTOMS

A. Adjust flapper chain assembly for proper slack.

B. Inspect, clean and, if necessary, replace

flapper ball and/or seat.

PROBABLE CAUSES

CORRECTIVE ACTION

1. Float valve turns on/off

by itself without toilet

being flushed.

A. No slack in flapper chain assembly, holding

flapper off seat.

B. Flush valve flapper ball worn, dirty or

misaligned with flush valve seat; or seat

corroded so flapper will not seal.

A. Shut off water supply; remove float valve cap

assembly by rotating 1/8 turn counterclockwise.

Cover uncapped lower valve unit with an

inverted cup (holding it to prevent overspray),

and turn water on and off a few times. Clean

float valve seal surface (located under float

valve cap). Replace float valve cap assembly

by engaging lugs and rotating 1/8 turn

clockwise. Turn water on. Install filter in supply

line to prevent recurring problems.

B. Replace seal.

C. During fill cycle, hold float under water a few

seconds to allow it to fill with water ballast.

Adjust float by adjust the cross-shaped thread

on float rod and sliding float up or down on

float rod until water level is at marked water

line.

D. Replace flush ball.

E. Turn trip lever nut clockwise to loosen until

trop lever no longer binds.

A. Foreign particles lodged under the float valve

seal (located under float valve cap).

B. Float valve seal (located under float valve cap)

may be cracked or split.

C. Tank water level set above overflow level.

D. Water leaking past flush ball.

E. Trip lever binding, holding flush ball open.

A. During fill cycle, hold float under water a few

seconds to allow it to fill with water ballast.

B. Adjust the cross-shaped thread on float rod

until water level is at marked water line.

A. Valve float cup does not contain enough water

to provide required ballast.

B. Float height incorrect.

4. Long or noisy tank fill

cycle.

A. Perform Corrective Action 2.A.

A. Plugged valve inlet or supply line.

A. Adjust water tank level.

B. Unclog trapway; clean rim holes.

C. Clear obstruction from soil pipe or vent.

D. Open supply shut-off valve.

A. Water level is too low.

B. Trapway or rim holes are obstructed.

C. Soil pipe or vent is obstructed.

D. Supply shut-off valve not fully open.

5. Poor flush.

A. Toilet trapway is obstructed.

B. Soil pipe or vent is obstructed.

A. Use plunger to unclog.

B. Clear obstruction from soil pipe or vent pipe.

6. Toilet overflows.

7. Toilet does not activate.

A. Reconnect the chain.

A. Chain is not connected to lift rod or flush valve.

2. Float valve continues to

run, allowing water to

enter tank.

3. Incorrect water level

height.

1033004-T01-A