AVV-711 Quick Book

45

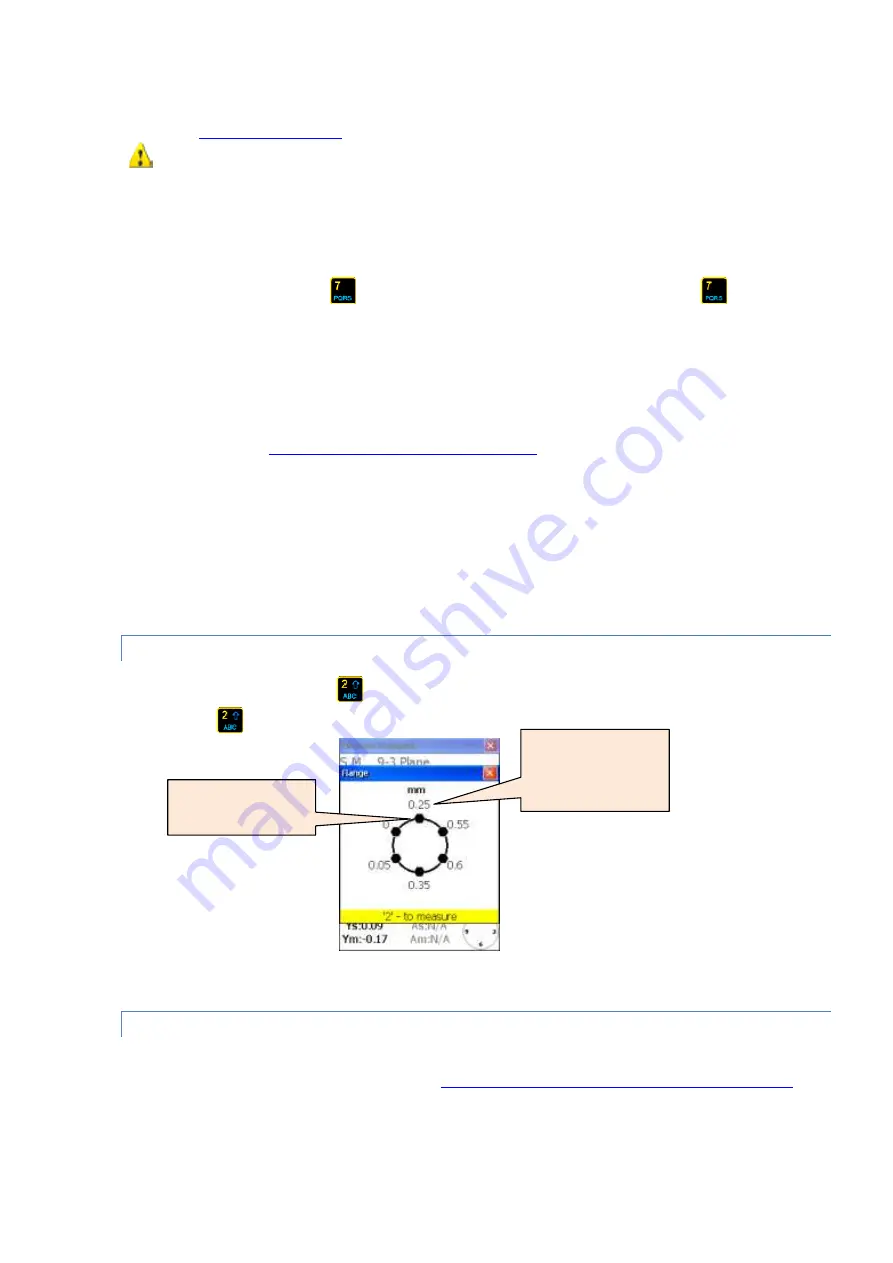

To eliminate angularity (gap) correct moveable machine central axis angle using shims with values

showed in

screen.

Do not change movable machine lateral position, while inserting/removing shims.

Single coordinate(Y) offset live alignment procedure

9-3 plane live alignment

To start 9-3 plane live alignment shafts should be in 9 or 3 o’clock position.

If you need to turn shaft press

to freeze. Turn shafts to desired position and press

to thaw. Do

not forget enter manual angle. After some averaging time desired plane should become enabled for live

update(blinking green checkbox appears at plane header) correction Loosen moveable machine feet and

start adjusting the movable machine position on 9-3 axis only.

6-12 plane live alignment

To start 6-12 plane live alignment shafts should be in 6 or 12 o’clock position.

Do shafts rotation as

described in 9-3 plane alignment section

. Plane 6-12 should become enabled for

live update. Loosen moveable machine feet and start adjusting the movable machine position on 6-12

axis only.

Biaxial (Y, X) offset live alignment procedure

Biaxial live alignment procedure mostly the same as the single coordinate procedure except that there no

need to turn shafts in to predefined positions and no need to turn shafts when change from horizontal to

vertical alignment and vise versa, but highly recommended turn shaft close to 45 evenly degree (45-135-

225-315) for equalize measurement errors.

7.4.1 TO VIEW BOLTS CORRECTIONS

To view bolts corrections press

Bolts corrections values screen appears. To close bolts corrections

screen press

CONTINUE WORK AFTER THE TRANSDUCERS POSITION CHANGED

Before continue work after the transducers position changed it is necessary to take two initial position

measurement points. See horizontal alignment

continue work after the transducers position changed

for

details.

Bolt correction value

(shim thickness)

12 o’clock position