AVV-711 Quick Book

12

3.0 MACHINE ALIG NMENT

·

Mount the Measuring transducer units on the shafts of the (S) and (M) machines

·

Select program according to the application of machine to be measured

·

Input the distances between the (S) and (M) units, the coupling and the movable machine

feet

·

Press

to record readings from the measuring units at three different positions of the

shafts

·

Adjust the machine feet position of the movable machine in accordance with correction

results of the calculated value on control screen

Attention!

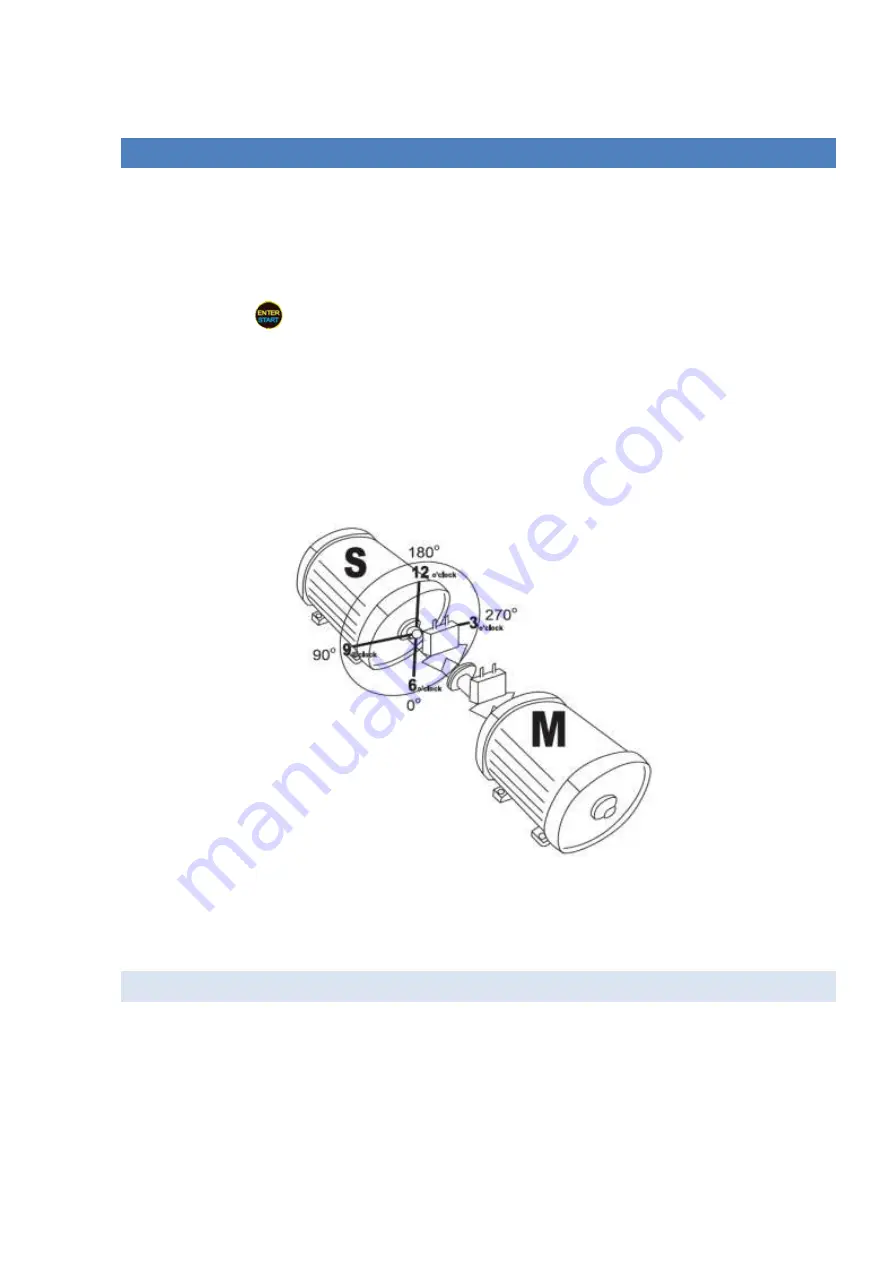

While making the measurement, it is necessary to observe and understand the orientation on rotation

direction of the shafts with the (S) and (M) measuring transducer units with regard to the relative position

of the (S) and (M) machines as in Fig.4.

Fig 4.

Fig. 4 shows the view of (S) machine from the (M) end view, at the 12:00 o’clock position. The measuring

transducer units have marking (S) and (M) on the top of each unit, should be mounted with brackets onto

the shafts of the (S) stationary and (M) movable machine respectively.

3.1 INPUT MEASURE MENT DATA

AVV-711 system function is based on the measurement of the laser beam movement on the detector

receiver’s window during the turning of shafts with the measuring units mounted.

To enable the System to carry out the shaft alignment calculation, it is necessary to record the

measurement data in minimum three positions of the shafts rotation. turning the shafts in the range of

180º is sufficient.