AUTO PICLE-S

26

1 Operate the power switch for start-stop changeover.

2 Be sure to set it in the stop position unless the machine is to be

moved.

5.2

Ignition and flame adjustment

Adjust the gas pressure according to the Cutting Data. The data shows

the pressure when all the valves are open. Readjust the pressure after

ignition.

Flame adjustment method

1 Open the fuel gas valves ¼ to ½ a turn.

2 Light the torch with an igniter.

3 Open the preheating oxygen valve gradually until a white cone of the

standard flame has been obtained. The incandescent area should be

uniform and about 5 - 6 mm in length.

4 Open the jet oxygen valve fully.

5 Readjust the flame if its condition has changed.

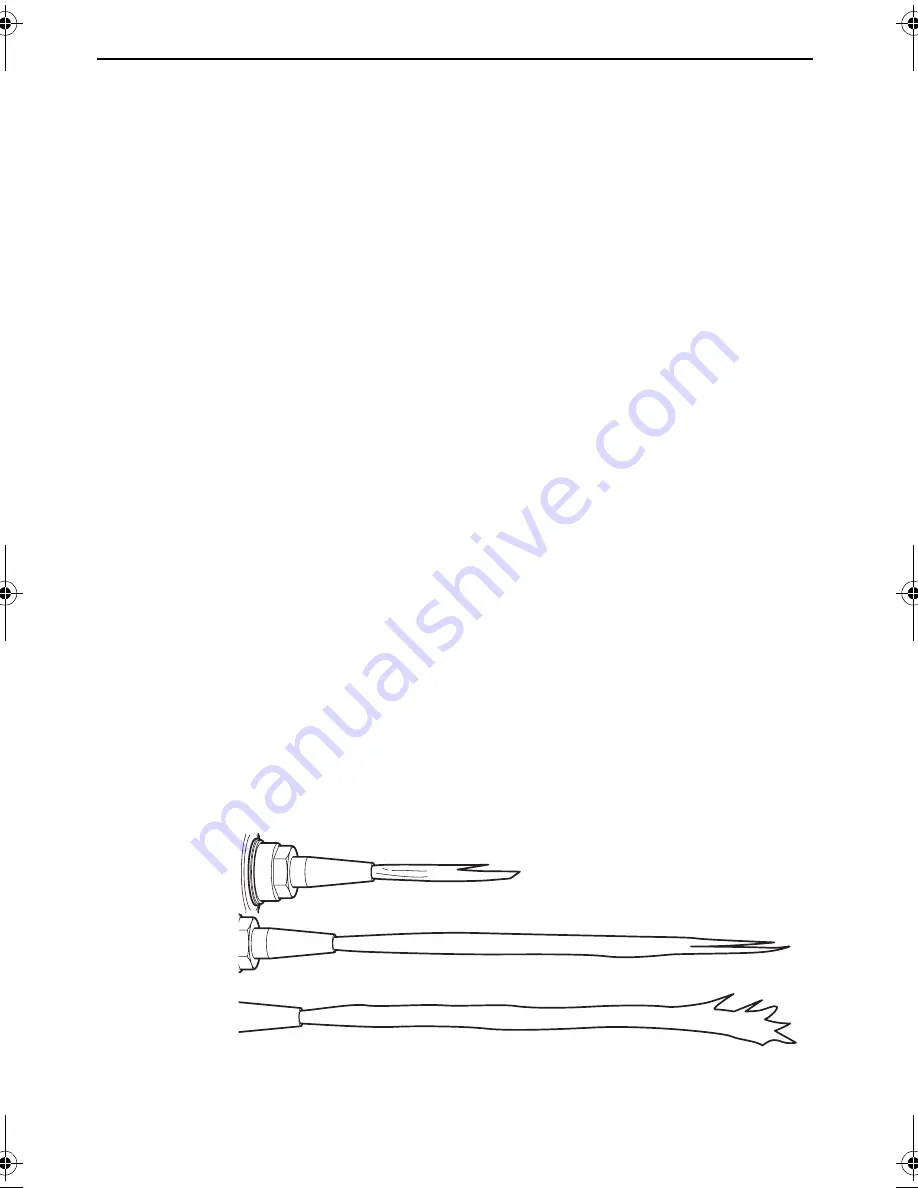

A disorderly flow of the jet oxygen will adversely affect the quality of the

cutting surface. In such a case, the jet oxygen channel has to be cleaned.

1 Close both the gas and the preheat oxygen valves before cleaning

the jet oxygen opening.

2 Clean the tip with a suitable cleaning needle while the jet oxygen is

flowing.

Neutral flame ensures a good quality cut surface. (Oxidized flames may be

used for bevel cutting.) The oxidized flame shortens the jet oxygen flow,

causing slug deposition or melting the upper edge of the cut surface.

Excessively high jet oxygen pressure will cause the same effect.

figure 5 - 2

Oxidizing flame

Neutral flame

Carburizing flame

Auto Picle-S.book Page 26 Thursday, April 11, 2002 11:15 AM

Summary of Contents for AUTO PICLE-S

Page 1: ...AUTO PICLE S REMOTE CONTROL GAS MOTORIZED PIPE CUTTING MACHINE KOIKE SANSO KOGYO CO LTD...

Page 11: ...AUTO PICLE S 10...

Page 13: ...AUTO PICLE S 12...

Page 25: ...AUTO PICLE S 24...

Page 31: ...AUTO PICLE S 30...

Page 37: ...AUTO PICLE S 36...

Page 39: ...AUTO PICLE S 38 8 2 Assembly drawing figure 8 2...

Page 40: ...AUTO PICLE S 39 9 Parts list 9 1 Body unit...

Page 43: ...AUTO PICLE S 42 9 2 Driving unit...

Page 46: ...AUTO PICLE S 45 9 3 Electrical and gas unit...

Page 49: ...AUTO PICLE S 48 9 4 Guide rail...

Page 51: ...AUTO PICLE S 50...