AUTO PICLE-S

31

6

Maintenance and inspection

Refer to the following for inspection and maintenance of the machine and

use the machine under the best operating conditions at all times.

Maintenance is only to be conducted by a qualified professional.

6.1

Disassembly

6.1.1 Disassembly for maintenance and inspection of electric parts

Control box

Remove the four round crosshead

screws (M4x6) (1) that are securing

the operation panel sheet.

Maintenance and inspection of

electric parts will be possible as

shown in figure 6 - 1.

Motor

Remove the four round crosshead

screws (M4x6) (2) and four round

crosshead screws (M3x6) (3) that are

securing the motor covers (4) and (5)

and remove the motor covers.

By removing the four round

crosshead screws (M4x16) (7) that

are securing the motor (6),

maintenance and inspection of the

motor will be possible as shown in

figure 6 - 2.

1

figure 6 - 1

3

3

2

7

4

6

5

figure 6 - 2

Auto Picle-S.book Page 31 Thursday, April 11, 2002 11:15 AM

Summary of Contents for AUTO PICLE-S

Page 1: ...AUTO PICLE S REMOTE CONTROL GAS MOTORIZED PIPE CUTTING MACHINE KOIKE SANSO KOGYO CO LTD...

Page 11: ...AUTO PICLE S 10...

Page 13: ...AUTO PICLE S 12...

Page 25: ...AUTO PICLE S 24...

Page 31: ...AUTO PICLE S 30...

Page 37: ...AUTO PICLE S 36...

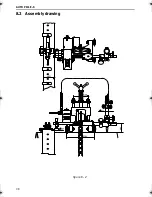

Page 39: ...AUTO PICLE S 38 8 2 Assembly drawing figure 8 2...

Page 40: ...AUTO PICLE S 39 9 Parts list 9 1 Body unit...

Page 43: ...AUTO PICLE S 42 9 2 Driving unit...

Page 46: ...AUTO PICLE S 45 9 3 Electrical and gas unit...

Page 49: ...AUTO PICLE S 48 9 4 Guide rail...

Page 51: ...AUTO PICLE S 50...