-18-

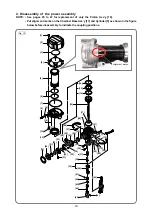

Fig. 20

• Turn the Special Nut M58

[13]

and remove it from the Cylinder

[5]

.

• Remove the Chamber Base Ass’y

[11]

from the Cylinder

[5]

being careful not to damage the sealing

surfaces.

• Remove the two O-rings (I.D 55.5)

[6]

from the Cylinder

[5]

.

• Remove the Slide Ring

[14]

and X-ring

[15]

from the Piston Ass'y

[16]

.

• Remove the Piston Bumper

[17]

from the Nose

[18]

.

• Remove the Retaining Ring D52

[19]

from the Nose

[18]

and pull out the Bearing Holder

[20]

and Pin

Wheel

[28]

.

NOTE: The Pin Wheel [28] can be removed only after removing the Piston Ass'y [16].

• Remove the Ball Bearing 6000VV

[21]

and Ball Bearing 6902VV

[30]

from the Pin Wheel

[28]

.

• Remove the Needle Roller D3

[31]

from the Pin Wheel

[28]

and then remove the Position Detector

[23]

.

• Remove the eight Needle Rollers D4

[33]

and one Needle Roller D4.5

[24]

from the Pin Wheel

[28]

.

Remove Wheel Spring (A)

[32]

, Wheel Spring (B)

[29]

, and Pin (A)

[34]

.

• Remove Felt (P)

[25]

from the Pin Wheel

[28]

.

Fit the claws of the J-400 special socket in the

notches on the Cylinder

[5]

(4 places).

J-400

Repair tool number "J-400"

J-400 special socket (Code No. 372798)

• Apply 0.5 g or more oil to the top and bottom of the Special Nut M58

[13]

all around.

• Leave the Special Nut M58

[13]

as it is for at least 2 hours.

• Loosen the Special Nut M58

[13]

.

• If it is hard to loosen, apply additional oil to the Special Nut M58

[13]

and leave it for more than half a day. Then loosen it again.