-29-

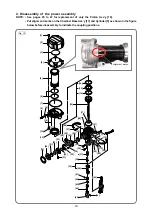

Fig. 40

Fig. 41

CAUTION: • Be sure to switch to the maintenance mode (see page 8) and move the Piston Ass'y [16]

down to the bottom dead point before feeding or discharging compressed air.

• Be sure to use the specified reduction valve set when feeding compressed air.

• An oil-free compressor should be used to feed compressed air to the nailer.

1. Moving the piston down to the bottom dead point

• Turn on the nailer and switch to the maintenance mode. (See page 8.)

• Repeat the steps below three or four times until the Piston Ass'y

[16]

reaches the bottom dead point.

(1) Move the Feeder Knob

[106]

down to reset the dry-fire lockout mechanism.

(2) Press the Probe

[45]

against a piece of wood.

(3) Pull the Trigger

[57]

.

• Check that the driver blade of the Piston Ass'y

[16]

protrudes from the blade guide.

2. Feeding compressed air

• Check that the battery is not mounted in the nailer body.

• Prepare the J-394 reduction valve set (16 GA) specified below.

Model name indicated on label

Repair tool number

Preset feeding pressure

NT 1865DM

J-394 (Code No. 371208)

0.5±0.03 MPa (5.1±0.3 kgf/cm

2

)

[106]

Feeding compressed air

[45]

1

2

3

Pressure regulator

Charge screw

Repair tool number

and feeding pressure

Air plug*

*: Replace the air plug according to your air compressor.

(Air plug: 1/4" NPT pipe thread taper)

O-rings

Model name and repair tool

number are indicated on the label.

Blade guide

Driver blade

[57]