-3-

Problem

Possible cause

(*: Most common cause)

Inspection method

Corrective action

3.

Nails cannot

be driven

into the

workpiece

completely:

the lower

heads

cannot be

made flush

with the

workpiece

surface.

• No compressed air in the

nailer

• Compressed air leak

• Fill up the nailer with

compressed air, leave the

nailer still for one day, and

then check the nailing work.

• Check the sealing surfaces,

X-rings, and O-rings inside

the cylinder, piston, chamber

cover, and chamber base for

flaws, unwanted objects, and

other failures.

• Supply compressed

air.

• Disassemble the

nailer and clean the

chamber, piston, and

their vicinity.

• Replace the sealing

parts.

• Probe is not set at the hole

of the metal connector.

• Set the probe at the hole of

the metal connector surely

and drive nail.

―

4.

Nails are

driven out of

hole on the

metal

connector

• Probe is not set at the hole

of the metal connector.

• Set the probe at the hole of

the metal connector surely

and drive nail.

―

• Broken or worn-out probe

• Check if the probe is broken

or worn out.

• Replace defective

parts.

• Broken or worn-out nail

support (B) or spring (B) or

urethane shaft

• Check if nail support (B) is

broken or worn out.

• Check whether the nail

support (B) moves smoothly

and the load of spring (B) and

urethane shaft is felt. When

checking, disassemble the

magazine referring to page

10.

• Replace defective

parts.

5.

Nails jam.

*• Abnormal nails are used

(e.g., bent nails, abnormal

collation)

• Nails are not completely fed

into the injection port.

• Check whether the magazine

is correctly loaded with

specified nails.

• Use specified nails.

• Remove abnormal

nails and load the

nailer with proper

nails.

• Worn-out piston tip

• Check whether the piston tip

is excessively worn.

• Replace defective

parts. See page 25.

• Wood material too hard to be

nailed

• Drive nails into soft wood and

check whether nails jam.

• This nailer is not for

hard wood.

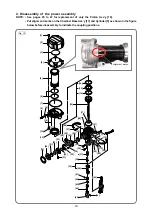

• Piston slide surface trouble

(e.g., galling, break)

• Check the surfaces on which

the piston slides (blade

guides (A), (B), pushing

levers (A), (B), probe, and

nail support (B)).

• Replace defective

parts.

<Magazine section>

• Nail feeder trouble (e.g.,

deformation, burring, break)

• Check the nail feed section

for any trouble (e.g., burring,

deformation, break,

excessive wear).

• Remove burring.

• Correct the

deformed portion.

• Replace defective

parts.

• Nail guide groove of blade

guide (B) too narrow or wide

• Nail guide groove trouble

(e.g., protrusion, burrs,

excessive wear) of blade

guide (B) or nail support (A)

• Nail guide groove of the

magazine too narrow or wide

• Nail guide section trouble

(e.g., deformation, burrs) of

the magazine

• Load nails in the nailer and

check that the nailer works

normally.

• Remove burring.

• Replace defective

parts.