TECHNICAL HANDBOOK

INDUSTRIAL ROLLER SHUTTER_(RSM)

KOLLIAS Ltd.

Page 28/46

D.Z. –Ver.1

st

– 08/12/17

Address:

3rd km. National Highway Katerini - Thessaloniki

Katerini

Postal address:

P.O. Box : 91

60100, Katerini

Tel.:

+30 23510 36036

Fax:

+30 23510 45630

Web: www.kolliasdoors.com

Kollias Ltd. in support of its customers and the optimum utilization of its products, created the

following installation guide for industrial roller shutters. In order to highlight the high quality of the

product, the way of installation and proper operation is a key element in avoiding damage and

malfunctions. The following steps describe in detail the process of the installation of the

Industrial Roller

Shutters

.

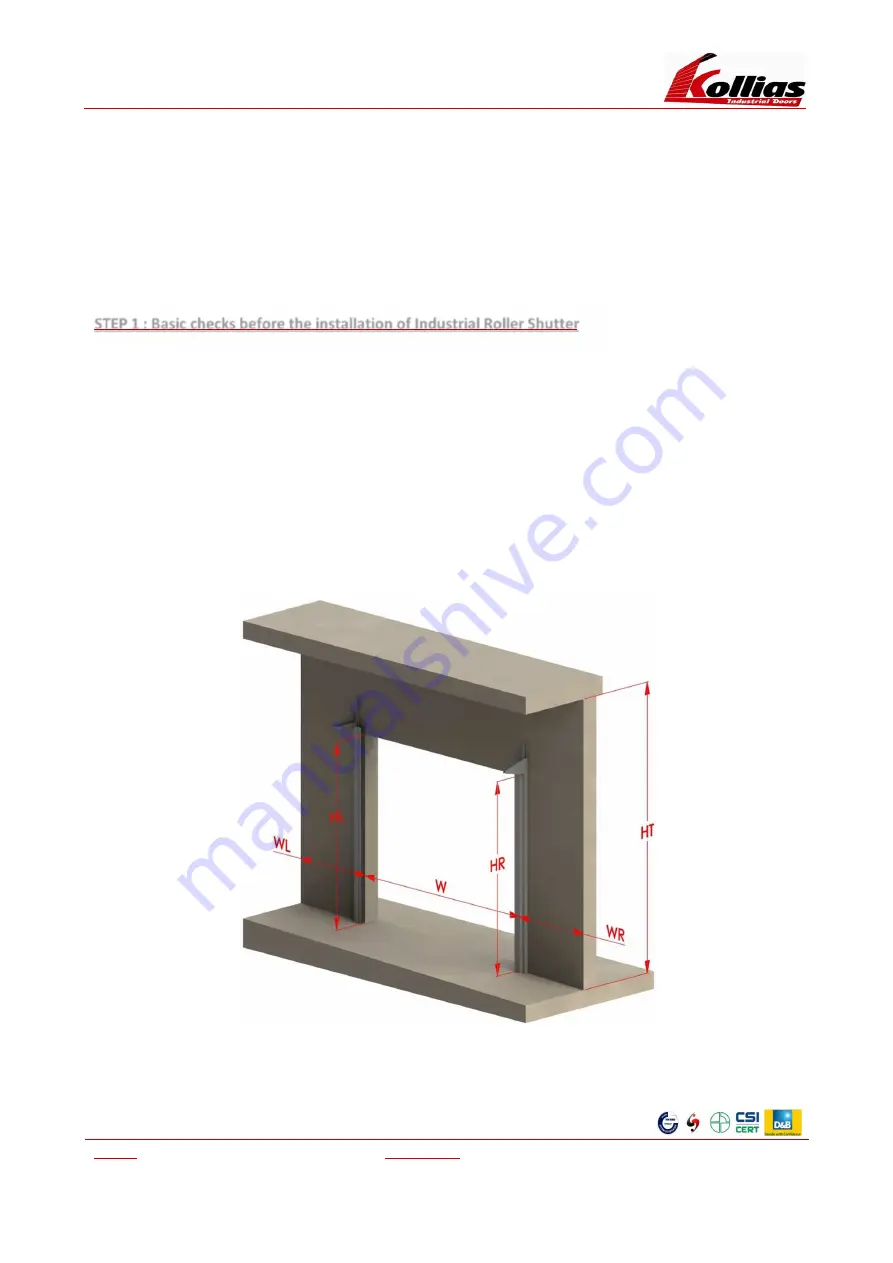

STEP 1 : Basic checks before the installation of Industrial Roller Shutter

Before starting any installation work, make sure that the right space (WR) and left (WL) of the

opening as well as the total height (HT) is sufficient to fit the guides (this is not required when the

installation is in "tunnels", meaning between the walls. Also, a check should be made if the floor is tilted

to make the necessary corrective movements by cutting a section of the lower part of the guide, which

will be placed in the highest altitude position (Figure 1). The purpose of the process of controlling the

height difference of the floor is that after lifting and supporting the guides, the roller bearings must be at

the same height.

Figure 1