II

Installation

II.1

Important instructions

l

Protect the servo amplifier from impermissible stresses. In particular, do not let any

components become bent or any insulation distances altered during transport and handling.

Avoid contact with electronic components and contacts.

l

Check the combination of servo amplifier and motor. Compare the rated voltage and

current of the units.

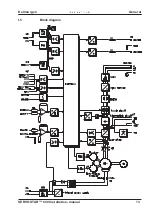

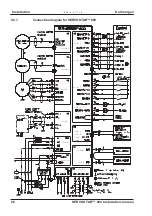

Carry out the wiring according to the connection diagram in Chapter II.3

l

Make sure that the maximum permissible rated voltage at the terminals L1, L2, L3 or +DC,

–DC is not exceeded by more than 10% even in the most unfavourable case

(see EN 60204-1 Section 4.3.1). An excessive voltage on these terminals can lead to

destruction of the regen circuit and the servo amplifier.

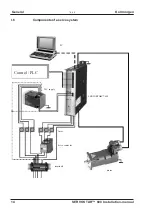

Use the SERVOSTAR™ 600 servo amplifiers only on an earthed 3-phased supply system,

to drive a synchronous servomotor of the 6SM series.

l

The fusing of the AC supply input and the 24V supply is installed by the user (

ð

I.7.1) .

l

Take care that the servo amplifier and motor are properly earthed. Do not use painted

(non-conductive) mounting plates.

l

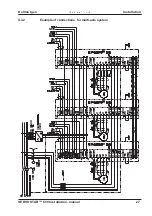

Route power and control cables separately. We recommend a separation of at least 20 cm.

This improves the interference immunity required by EMC regulations. If a motor power

cable is used which includes cores for brake control, the brake control cores must be

separately shielded. Earth the shielding at both ends (

ð

l

Install all heavy-current cables with an adequate cross-section, as per EN 60204. (

ð

l

Wire the BTB/RTO contact in series into the safety circuit of the installation.

Only in this way is the monitoring of the servo amplifier assured.

l

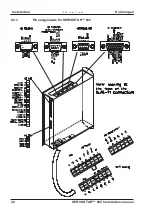

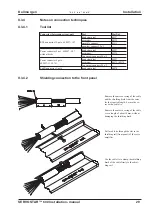

Install all shielding with large areas (low impedance), with metallised connector housings

or shield connection clamps where possible. Notes on connection techniques can be found

in Chapter II.3.4.2 .

l

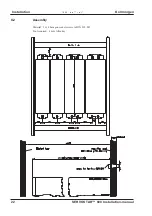

Ensure that there is an adequate flow of cool, filtered air into the bottom of the switchgear

cabinet.

Observe Chapterl I.7.2 .

l

It is permissible to alter the servo amplifier settings by using the operator software.

Any other alterations will invalidate the warranty.

Caution

Never disconnect the electrical connections to the servo vamplifier while it is live.

In unfavourable circumstances this could result in destruction of the electronics.

Residual charges in the capacitors can have dangerous levels up to 300 seconds after

switching off the mains supply voltage. Measure the voltage in the DC-link (+DC/-DC),

and wait until the voltage has fallen below 40V.

Control and power connections can still be live, even when the motor is not rotating.

SERVOSTAR™ 600 Installation-manual

21

Kollmorgen

02.99

Installation