AKI-CDB-MOD-12T | SAFETY PRECAUTIONS

Do not replace expansion unit unless power has been switched off or the area is known to

be non-hazardous.

NE REMPLACEZ L'UNITÉ D'EXTENSION QUE SI LE

COURANT A ÉTÉ COUPÉ OU SI LA ZONE EST JUGÉE NON DANGEREUSE.

•

This product contains a battery; this must only be changed in an area known to be non-hazardous.

•

Replace the battery with a BR 2032 battery. Use of another type of battery may present a risk of

fi

re or explosion.

Battery may explode if mistreated. Do not recharge, disassemble or dispose of in

fi

re.

LA BATTERIE PEUT EXPLOSER EN CAS DE MAUVAISE MANIPULATION.

NE LA RECHARGEZ PAS, NE LA DÉMONTEZ PAS ET NE LA JETEZ

PAS DANS LE FEU.

•

For use on a

fl

at surface of a type 4X enclosure indoor use only.

•

Use minimum 75°C copper conductors only.

•

To make wiring connections to the power supply connector, follow the table with cable and torque

speci

fi

cations below:

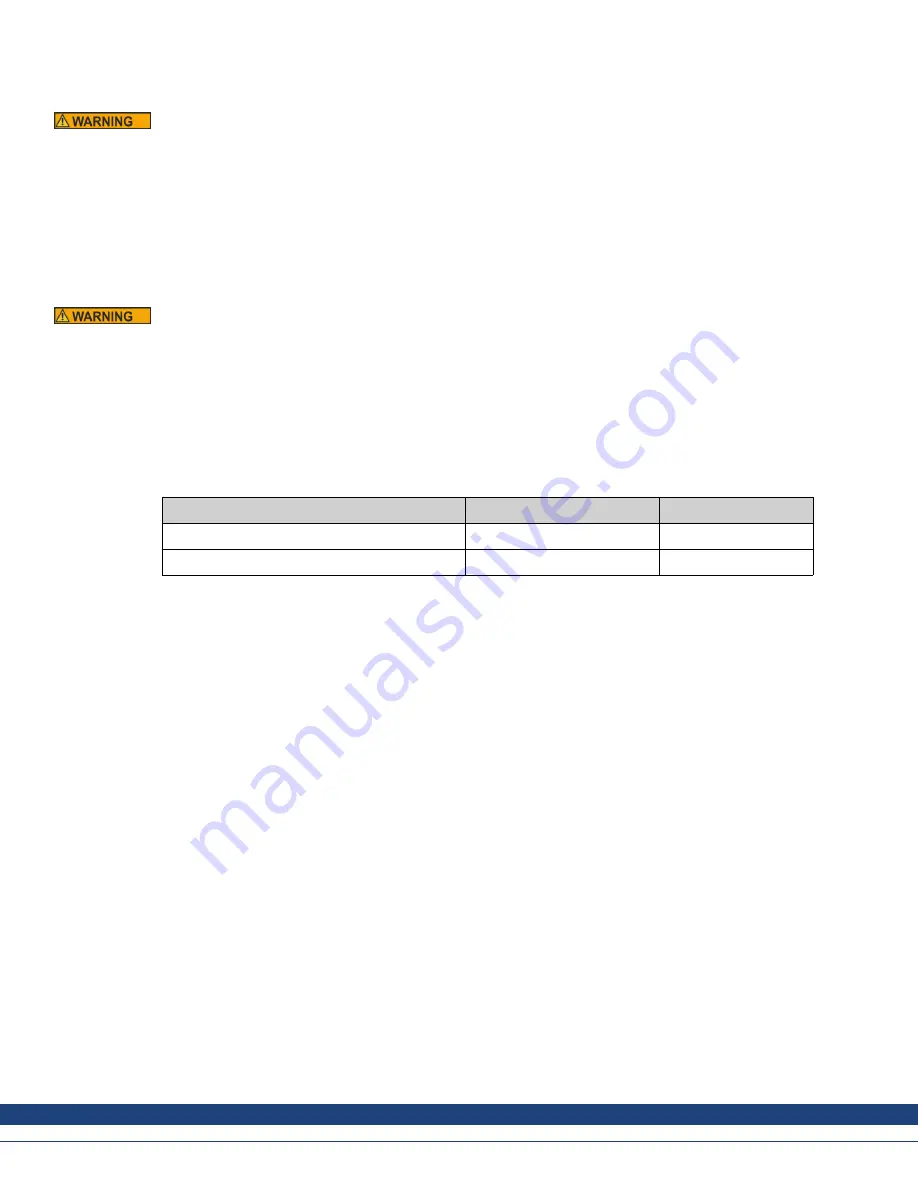

Terminal Block Connector

Wire Size

TQ Lb.In.

X1/X100 Phoenix connectors

AWG 30–12

5–7

X1/X100 Anytek connectors

AWG 24–12

3.5

•

These devices are Class 2 supplied programmable controllers (industrial PCs) for the use in

industrial control equipment and are intended to be (front) panel mounted (Type 1 and 4x for

indoor use only).

Caution:

The enclosure provides a degree of protection of at least IP20, but when installed in an

apparatus, it should meet IP54.

LE BOÎTIER OFFRE UN DEGRÉ DE PROTECTION D'AU MOINS IP20, MAIS

LORSQU'IL EST INSTALLÉ DANS UN APPAREIL, IL DOIT ÊTRE DE CLASSE IP54.

2.3

During Installation

•

The HMI panel is designed for stationary installation on a plane surface, where the following

conditions are ful

fi

lled:

–

no high explosive risks

–

no strong magnetic

fi

elds

–

no direct sunlight

–

no large, sudden temperature changes

•

Install the HMI panel according to the accompanying installation instructions.

•

Ground the HMI panel according to the accompanying installation instructions.

•

Only quali

fi

ed personnel may install the HMI panel.

•

Separate the high voltage, signal and supply cables.

ky

Kollmorgen | October 2014

6