M-SS-017-07 Rev C

21

SERVO

STAR

CD

Series 5

Error Codes

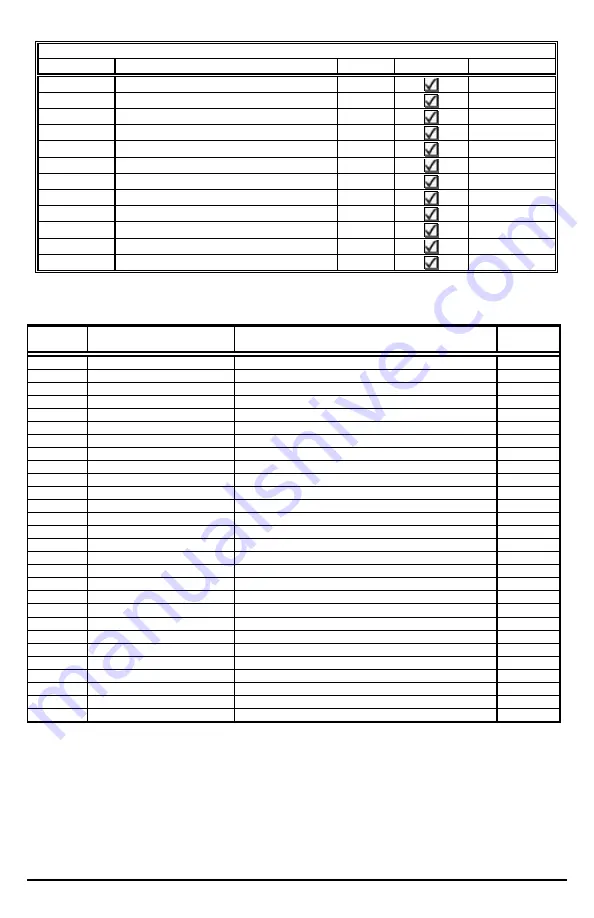

Error Code

Fault Message

Fatal

Non-Fatal

LED Display

84

Warning: Limit sw not routed

85

Move is pending

90

Incorrect password

91

Password protected

92

Capture during Homing

93

Homing during Capture

94

Capture process not done

95

Capture process not active

96

Capture process not enabled

97

ENCSTART while Aconfig

98

EnDat comm error

999

SERCOS test failure

F

ATAL

F

AULT

E

RROR

C

ODES

Status

Display

Fault Message

Possible Cause

Err #

t

Power stage OverTemp

overload, fan malfunction, power stage failure

1

o

OverVoltage

excessive decel rate*

2

P

OverCurrent

power stage surge current*

3

r0

External feedback fault

Feedback signal through C8 not correctly detected

4.0

r1

Resolver line break

break in resolver feedback detected

4.1

r2

RDC error

fault in resolver-to-digital converted detected

4.2

r3

Sine Encoder init fail

sine encoder card has not initialized properly

4.3

r4

A/B line break

break in encoder A/B input lines detected

4.4

r5

Index line break

break in encoder index line

4.5

r6

Illegal halls

illegal hall combination detected

4.6

r7

C/D line break

break in sine encoder C/D line detected

4.7

r8

A/B out of range

sine encoder A/B level out of range

4.8

r9

Burst pulse overflow

sine encoder fault

4.9

r10

Endat Communication Fault

Serial communication to the Endat Encoder failed

u

Under voltage

bus voltage is too low

5

H

Motor over temperature

motor overload caused overheating

6

A1

Positive analog supply fail

Failure in +12 V supply (regulated)

7.1

A2

Negative analog supply fail

Failure in –12 V supply (regulated)

7.2

J

OverSpeed

velocity

?

VOSPD

8

J1

OverSpeed

Velocity

?

1.8 x VLIM

8.1

E

EEPROM failure

Faulty EEPROM

9

e

EEPROM checksum fail

EEPROM checksum invalid on power up*

10

F

Foldback

System in FoldBack mode

12

d5

Positive over travel fault

PFB exceeded PMAX with PLIM=1

14.1

d6

Negative over travel fault

PFB exceeded PMIN with PLIM=1

14.2

d1

Numeric position deviation

Internal fault

15.1

d2

Excessive position deviation

PE > PEMAX

15.2

c

Communication interface

A communications fault has occurred

16

*These faults are only cleared by cycling power

StockCheck.com