M-SS-017-07 Rev C

22

SERVO

STAR

CD

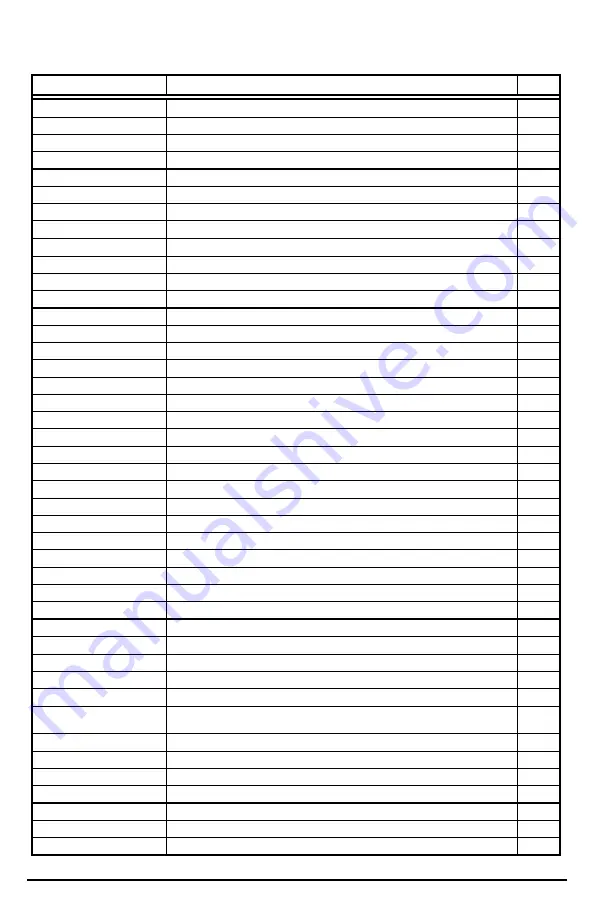

NON-FATAL ERROR CODES

Error Message

Possible Cause

Err #

No Error

no error was recorded

0

Unknown Command

Undefined command

20

Unknown Variable

undefined variable name

21

Checksum error

error on comm. message checksum (ACKMODE 2)

22

Drive Active

drive needs to be inactive for the requested command or variable

23

Drive Inactive

drive needs to be active for the requested command or variable

24

Value out of range

variable value out of range

25

Negative Number

variable must be

?

0

26

Not in proper Opmode

not in correct Opmode for specified command

27

Syntax Error

communication message syntax error

28

Tune Failed

auto tuning failed

33

Bad Bandwidth

AutoTuning BW is out of range

34

Bad Stability

bad stability

35

Not programmable

variable is read-only

36

Current loop design failed

CONFIG failed due to current loop design failure

37.01

MENCRES out of range

CONFIG failed due to MENCRES

37.02

MENCOFF out of range

CONFIG failed due to MENCOFF

37.03

MSPEED out of range

CONFIG failed due to MSPEED

37.04

MBEMF out of range

CONFIG failed due to MBEMF

37.05

MJ out of range

CONFIG failed due to MJ

37.06

ACC out of range

CONFIG failed due to ACC

37.07

DEC out of range

CONFIG failed due to DEC

37.08

DECSTOP out of range

CONFIG failed due to DECSTOP

37.09

VLIM out of range

CONFIG failed due to VLIM

37.10

VOSPD out of range

CONFIG failed due to VOSPD

37.11

VSCALE out of range

CONFIG failed due to VSCALE

37.12

O1TRIG out of range

CONFIG failed due to O1TRIG

37.13

O1RST out of range

CONFIG failed due to O1RST

37.14

DISSPEED out of range

CONFIG failed due to DISSPEED

37.15

MENCTYPE out of range

CONFIG failed due to MENCTYPE

37.16

Communication error

Error at physical comm. layer

38

Not in proper COMPMODE

The REFRESH command was given with COMPMODE

?

3

39

EXT velocity param warning

D, H, R parameters for COMPMODE 3 do not have the proper relationship.

40

Vel loop design failed

The velocity loop can’t be con-figured with given parameters

41

Invalid EEPROM

The EEPROM test failed

42

Recording active

The requested command cannot be executed as it conflicts with a recording in

progress

43

Rec data not available

No data are available for the GET command

44

EEPROM is empty

Data cannot be loaded because the EEPROM is empty

45

Argument must be binary

Variable argument must be a power of 2

46

Burnin is active

The requested function cannot be executed during Burnin (a factory function)

47

Burnin is not active

Burnin (factory function) cannot be stopped if it is not active

48

Conflicts with ENCOUT

The requested value for VLIM conflicts with ENCOUT.

49

Conflicts with VLIM

The requested value for ENCOUT conflicts with VLIM.

50

StockCheck.com